Professional China China Self Cleaning Over Belt Hydraulic Motor Permanent Magnetic Separator to Iron Scrap and Steel Scrap and Mill Ball

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for Professional China China Self Cleaning Over Belt Hydraulic Motor Permanent Magnetic Separator to Iron Scrap and Steel Scrap and Mill Ball, Warmly welcome to cooperate and develop with us! we are going to continue to provide product or service with high quality and competitive rate.

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for China Belt Magnetic Separator, Cross Belt Magnetic Separator, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Let us join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to provide you with high quality and efficient services.

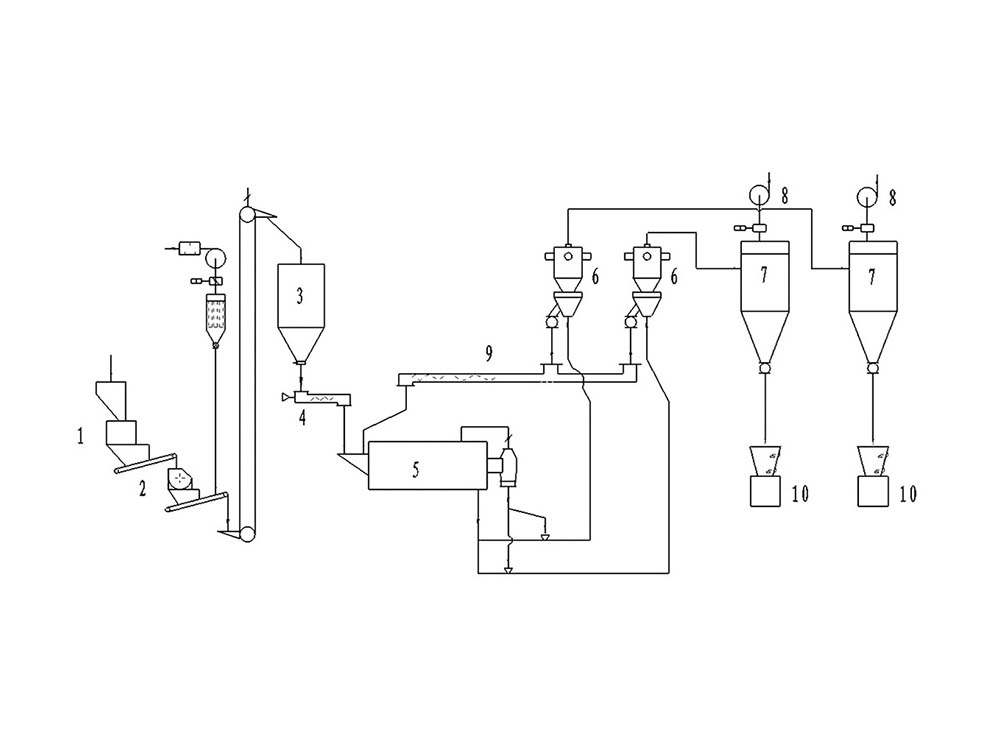

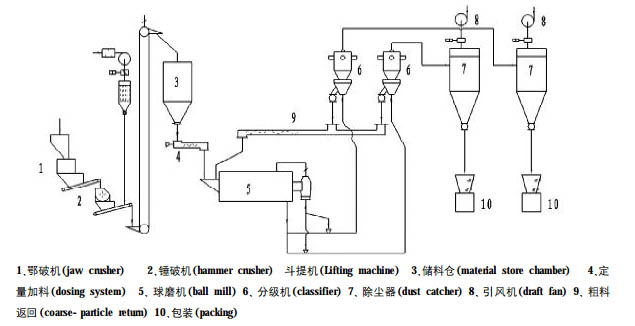

Application

◆Soft material: calcite, marble, limestone, barite, gypsum, slag etc.

◆Hard material: quartz, felspa, carborundum, corundum, fine cement etc.

Characteristics

◆Designed to the standards of ultrafine mineral manufacturing.

◆Optimized length-to-diameter factor of ball mill

◆Grid plate at the end of the ball mill discharges powder fluently, no dilating and no necessary to cool the tube

◆Grinding medium chosen according to customers’product, high filling rate and efficiency

◆Perfect match between drive station and energy consumption of grinding, energy saving to the fullest extent possible.

◆Forming a closed system with classifier, with negative pressure transport, without powder pollution.

Note: All of the parameters above are according to 1250 mesh GCC.

As different material from different places, the parameter is just for your reference.

Application Site