-

HMB Pulse Dust Collector

Brand: Huate

Product orign: China

Categories: Auxiliary Equipment

Application: Used for air purification by removing dust from the air in various industrial processes. It is designed to attract dust onto the surface of filter components and discharge purified gas into the atmosphere.

- 1. Efficient Dust Collection: Uses a reasonable air current combination to reduce the load on the dust catcher and pulse frequency.

- 2. High-Quality Sealing and Assembly: Features filter bags with special material sealing and a smooth frame, enhancing sealing performance and prolonging bag life.

- 3. High Dust Collection Efficiency: Offers different filter bags tailored to the working environment with a dust collecting efficiency of more than 99.9%.

-

HFW Pneumatic Classifier

Brand: Huate

Product orign: China

Categories: Classification

Application: The classifying device is widely used in chemicals, minerals (non-metallics like calcium carbonate, kaolin, quartz, talc, mica), metallurgy, abrasives, ceramics, fire-proof materials, medicines, pesticides, food, health supplies, and new materials industries.

- 1. Adjustable Granularity: Classifies product sizes to D97: 3~150 micrometers, with easily adjustable granularity levels.

- 2. High Efficiency: Achieves 60%~90% classification efficiency, depending on material and particle consistency.

- 3. User-Friendly and Eco-Friendly: Programmed control system for easy operation, operates under negative pressure with dust emissions below 40mg/m³ and noise levels under 75dB (A).

-

HF Pneumatic Classifier

Brand: Huate

Product orign: China

Categories: Classification

Application: This classifying device is suitable for industrial fields requiring precise particle classification, especially in applications where strict control of particle size is essential.

- 1. High Precision Classification: The specially designed classifying structure and high classification precision can strictly block large particles, ensuring product fineness.

- 2. Adjustability: The rotary speed of the classifying wheel and the air inlet volume can be adjusted to obtain the desired product, providing flexibility to meet different production requirements.

- 3. Efficient and Stable Performance: The single low-speed vertical rotor design ensures a stable flow field, offering high efficiency and robust performance.

-

HS Pneumatic Mill

Brand: Huate

Product orign: China

Categories: Classification

Application: Ideal for fine dry milling of various materials using high-speed airflow technology.

- 1. Energy Efficient: Consumes over 30% less energy compared to traditional jet mills.

- 2. High Precision & Efficiency: Self-diffluent micro-powder classifier and vertical impeller ensure high cutting precision and classifying efficiency.

- 3. Automated & Simple Operation: Fully sealed, negative pressure system with automated control for easy operation.

-

Dry Quartz-Processing Equipment

Brand: Huate

Product orign: China

Categories: Grinding

Application: Specially designed for the quartz-making field in the glass industry.

- 1. Pollution-Free Production: Silica lining prevents iron contamination during the sand production process.

- 2. Durable and Stable: High-quality alloy steel components ensure wear resistance and minimal deformation.

- 3. High Efficiency: Equipped with multiple grading screens and a high-efficiency Pulse Dust Collector for clean and efficient production.

-

CFLJ Rare Earth Roller Magnetic Separator

Brand: Huate

Product orign: China

Categories: Permanent Magnets

Application:Nonmetallic mineral industries,Dry primary separation of hematite and limonite, Dry separation of manganese ore.

Enhanced Magnetic System

Improved Efficiency

Customizable and Convenient -

HCT Dry Powder Electromagnetic Iron Remover

Applicable It is mainly used to remove magnetic substances in battery materials, ceramics, carbon black, graphite, flame retardants, food, rare earth polishing powder, photovoltaic materials, pigments and other materials. Working Principle When the excitation coil is energized, a strong magnetic field is generated at the center of the coil, which induces the magnetic matrix in the sorting cylinder to generate a high gradient magnetic field. When the material passes through, the magn... -

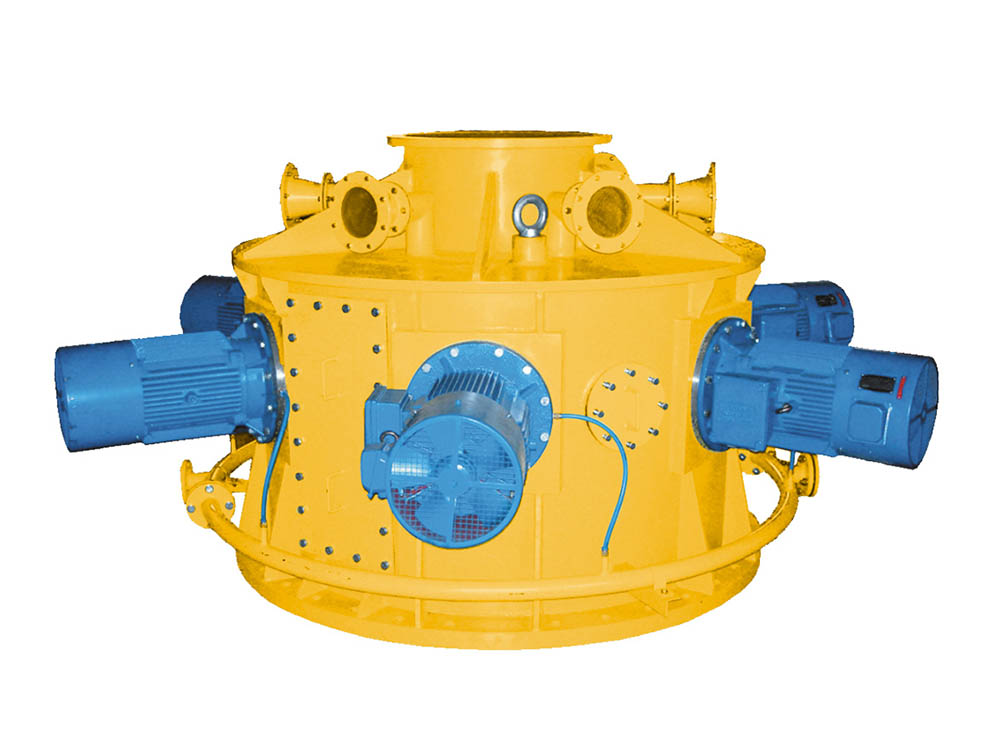

MQY Overflow Type Ball Mill

Application: The ball mill machine is a kind of equipment which is used to grind ores and other materials with various hardness. It is widely used in non-ferrous and ferrous metal processing, chemicals, building materials and other industries as the main equipment in grinding operation.

-

MBY (G) Series Overflow Rod Mill

Application: The rod mill is named after the grinding body loaded in the cylinder is a steel rod. The rod mill generally uses a wet overflow type and can be used as a first-level open-circuit mill. It is widely used in artificial stone sand, ore dressing plants, chemical industry the primary grinding industry in the power sector of the plant.