-

On-Line Energy-Saving And Environmental Protection Permanent Magnetic Stirrer

With the unique magnetic circuit design special treated alnico and alnico treated by special technique,it features with robust performance,hightemperature resistance and long service life.

-

Energy-Saving And Environmental Protection Permanent Magnetic Stirrer(side-installed)

With the unique magnetic circuit design and special treated alnico,it features with robust performance,hightemperature resistance and long service life.

-

Dry Powder Electro Magnetic Iron Remover

It is mainly used to remove magnetic substances in battery materials, ceramics, carbon black, graphite, flame retardants, food, rare earth polishing powder, photovoltaic materials, pigments and other materials.

-

Patented Technology Innovation Points

The magnetic system and the tank body are matched to the partition design, the magnetic curve is in pulsating distribution, with multi-pole cleaner separation, balancing concentrate grade and recovery rate, and the demagnetization within 10 years is not more than 3%.

-

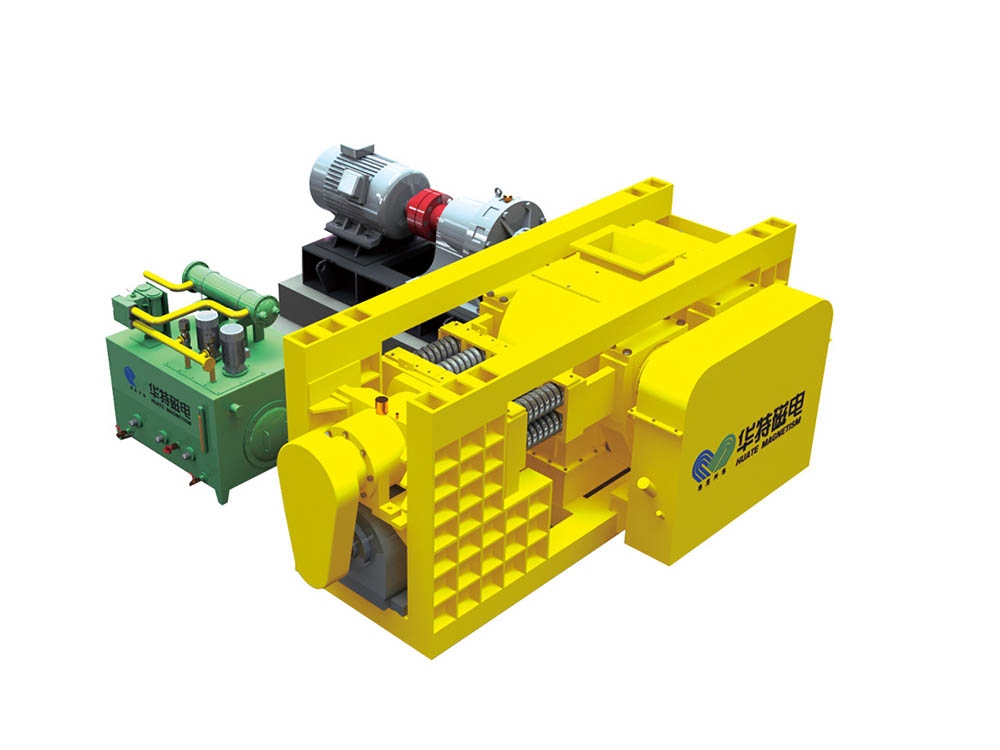

Series PGM Single Driving High Pressure Roller Mill

Application:

Single-drive high pressure grinding roll is specially designed to pre-grind the cement clinkers, the mineral dross, the steel clinkers and so on into

small granules, to ultra-crush the metallic minerals (iron ores, manganese ores, copper ores, lead-zinc ores, vanadium ores and others) and

to grind the non-metallic minerals (the coal gangues, feldspar, nephe-line, dolomite, limestone, quartz, etc.) into powder .

-

Series RCSC Superconducting Iron Separator

Application: To eliminate the ferric materials from the coal on the coal-transporting dock, so that charcoal of enhanced grade can be produced.

-

HTDZ Series Slurry Electromagnetic Filter

Application:

Remove the impurities and purify the non-metallic minerals, like silica sand, feldspar, kaolin etc. It can also be used in other industries, like to deal with the wasted water in steel plants, power-generation plants, and to cleanse the polluted chemical raw materials.

-

DCFJ Fully Automatic Dry Power Electromagnetic Separator

This equipment is used to remove weakly magnetic oxides,crumb iron rust and other contaminants from fine materials.It widely applies to material purification in refractory material,ceramics,glass and other non-metallic mineral industries,medical,chemical,food and other industries.

-

DCFJ Fully Automatic Dry Power Electromagnetic Separator

This equipment is used to remove weakly magnetic oxides,crumb iron rust and other contaminants from fine materials.It widely applies to material purification in refractory material,ceramics,glass and other non-metallic mineral industries,medical,chemical,food and other industries.

-

CGC Series Cryogenic Superconducting Magnetic Separator Roller Magnetic Separator

This series of products has an ultra-high background magnetic field that cannot be achieved by ordinary electromagnetic equipment, and can effectively separate weakly magnetic substances in fine-grained minerals.It is suitable for beneficiation of rare metals, non-ferrous metals and non-metallic ores, such as cobalt ore enrichment, impurity removal and purification of kaolin and feldspar non-metallic ores, and can also be used in sewage treatment and seawater purification and other fields.

-

CGT series high field strength drum permanent magnet magnetic separator

The CGT series high field strength roller permanent magnet separator is a high-tech product carefully developed by our company’s scientific and technological personnel. The product has applied for a national patent and passed national technical appraisal.

-

Completely non-ferrous metal separation production line

The sorting system equipment design absorbed the advanced technology and structure of similar foreign products, for recycling non-ferrous metal, instead of manual separation, largely to improve the product efficiency. The system can automatically separate iron, stainless steel, non-ferrous metal and non-metallic materials from materials ,which is a kind of material energy to be reused.