Patented Technology Innovation Points

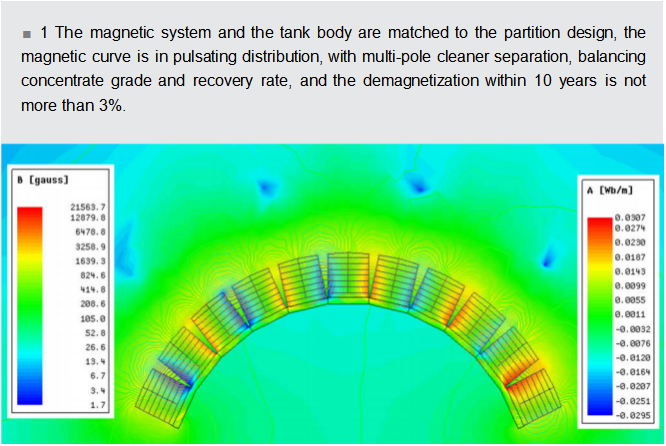

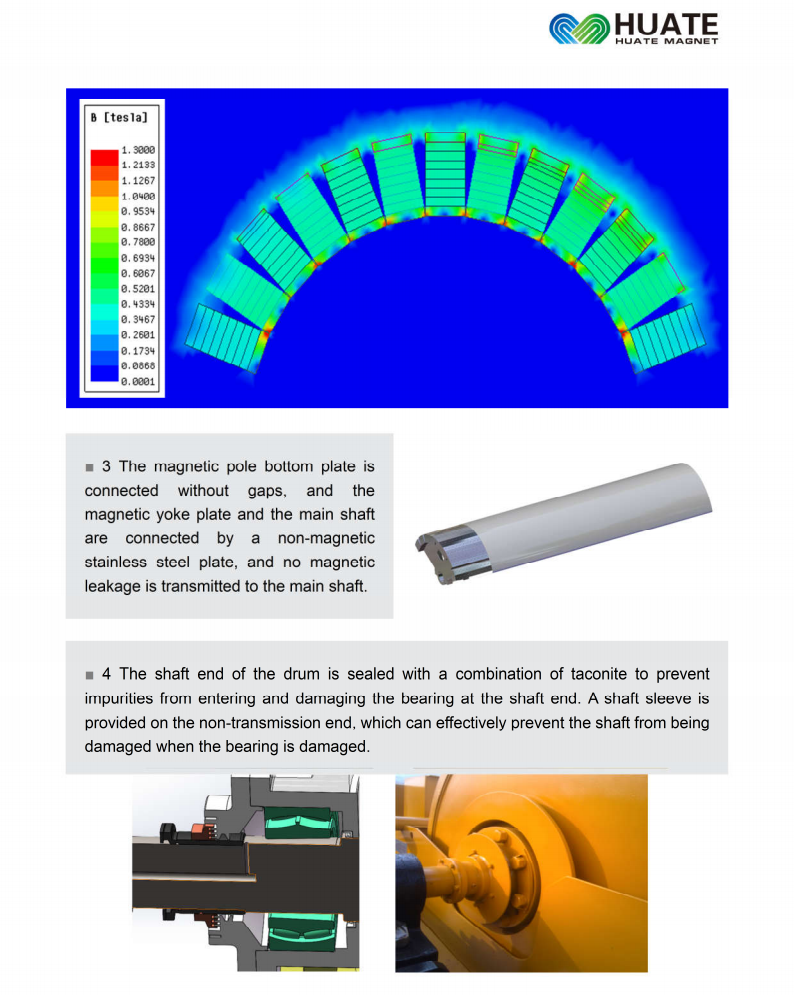

■ 2 Pulsating magnetic system: The magnetic system includes multiple sets of magnetic poles supported by sector-shaped magnetic isolation plates fixed on the main shaft. The gaps between each set of magnetic poles are equipped with secondary magnetic poles, and the shell of the drum is provided with a magnetic stirring device. During separation, the minerals adhering to the surface of the drum are effectively stirred, and the multi-pole magnetic system makes the minerals repeatedly agglomerate and disperse, which can greatly improve the iron ore grade. [Patent of pulsating concentration magnetic separator: ZL200620162175.3]

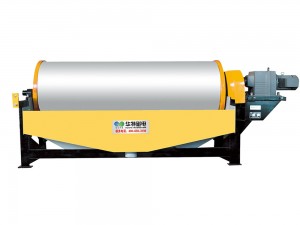

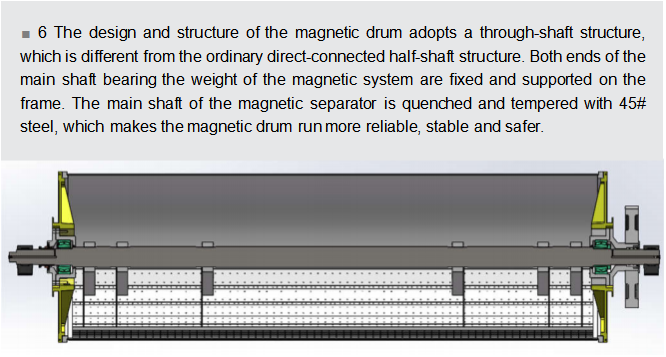

■ 7 The drum body is made of 304 stainless steel, and the surface wear-resistant layer is made of high-alumina ceramic sheet or integrated polymer wear-resistant rubber.

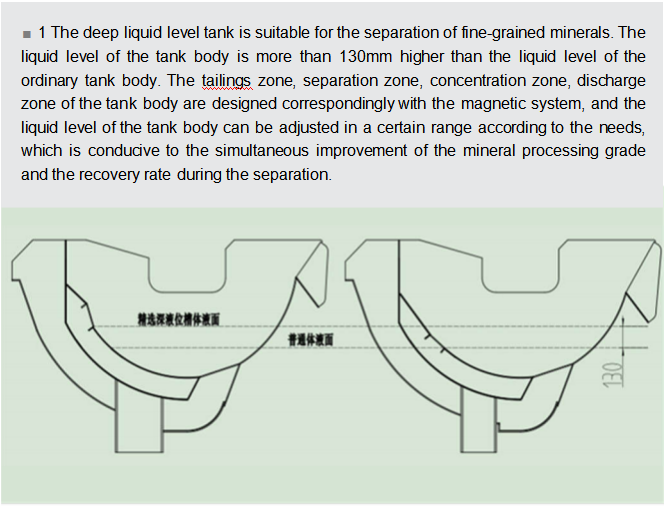

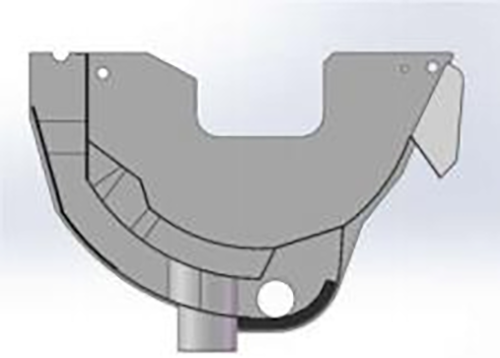

Innovation Point 2 Tank Body

■ 2 The contact surface of the tank body and the feeding slurry is lined with polymer wear-resistant rubber plate, and the bottom is lined with basalt cast stone plate, which ensures the service life of the tank body.

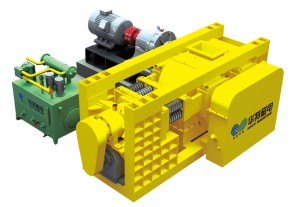

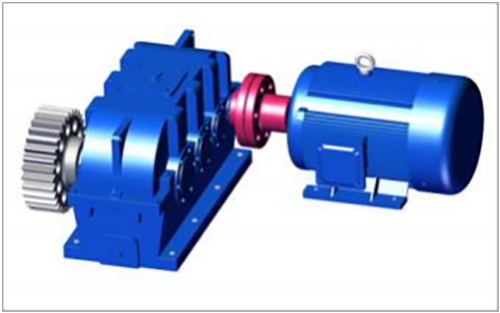

Innovation Point 3 Transmission Device

■ 1 Adopting hardened cylindrical gear reducer, suitable for all-weather work. Equipped with a first-class energy efficient motor and overload protector, the operation is stable and reliable.

■ 2 Fully sealed gear guard, reliable protection and sealing, suitable for grease lubrication or mixed oil lubrication.

| Main Technical Specifications | ||||||||

|

Model |

Drum size | Magneticinduction

intensity on drum surface mT |

Processing capacity |

Motor power kW |

Drum

rotation speed r/min |

Machine weight kg |

||

|

Diameter mm |

Length

mm |

t/h |

m3/h |

|||||

| CTB-618 | 600 | 1800 | 15-30 | 40-80 | 1.5 | 40 | 1150 | |

| CTB-718 | 750 | 1800 | 20-45 | 60-100 | 3 | 35 | 1900 | |

| CTB-918 | 900 | 1800 | 25-40 | 70-120 | 4 | 28 | 2700 | |

| CTB-1018 | 1050 | 1800 | 45-60 | 110-160 | 5.5 | 22 | 3100 | |

| CTB-1021 | 1050 | 2100 | 50-70 | 140-200 | 5.5 | 22 | 3500 | |

| CTB-1024 | 1050 | 2400 | 60-80 | 170-260 | 5.5 | 22 | 4000 | |

| CTB-1030 | 1050 | 3000 | 80-120 | 240-380 | 7.5 | 22 | 5000 | |

| CTB-1218 | 1200 | 1800 | 60-75 | 160-260 | 11 | 17 | 4800 | |

| CTB-1224 | 1200 | 2400 | 80-110 | 240-330 | 11 | 17 | 6000 | |

| CTB-1230 | 1200 | 3000 | 100-140 | 260-460 | 11 | 17 | 6600 | |

| CTB-1236 | 1200 | 3600 | 120-160 | 300-550 | 15 | 17 | 7500 | |

| CTB-1240 | 1200 | 4000 | 130-170 | 330-600 | 15 | 17 | 8550 | |

| CTB-1245 | 1200 | 4500 | 150-200 | 380-660 | 15 | 17 | 9360 | |

| CTB-1530 | 1500 | 3000 | 100-180 | 290-480 | 15 | 14 | 10500 | |

| CTB-1540 | 1500 | 4000 | 150-200 | 300-540 | 22 | 14 | 13500 | |

| CTB-1545 | 1500 | 4500 | 180-240 | 400-650 | 22 | 14 | 14700 | |

| CTB-1550 | 1500 | 5000 | 210-280 | 500-750 | 30 | 14 | 16500 | |

| CTB-1824 | 1800 | 2400 | 100-140 | 260-460 | 15 | 12 | 9100 | |

| CTB-1830 | 1800 | 3000 | 140-190 | 350-560 | 18.5 | 12 | 12300 | |

| CTB-1840 | 1800 | 4000 | 200-260 | 400-650 | 30 | 12 | 18500 | |

| CTB-1850 | 1800 | 5000 | 280-320 | 550-800 | 37 | 12 | 23000 | |

Note: Magnetic separators with different magnetic field strengths can be customized according to user needs (for reference only)

| CTB1018 | 3050 | 2020 | 1300 | / | 480 | 2 | 2250 | / | 800 | 750 | 2 | 1595 | 1276 | 1107 | / | 1190 | 1200 | / | 180 | / | / |

| CTB1021 | 3350 | 2020 | 1300 | / | 480 | 2 | 2550 | / | 1000 | 900 | 2 | 1595 | 1276 | 1107 | / | 1190 | 1200 | / | 180 | / | / |

| CTB1024 | 3660 | 2020 | 1300 | / | 480 | 3 | 2850 | / | 1250 | 600 | 2 | 1595 | 1276 | 1107 | / | 1190 | 1200 | / | 180 | / | 1375 |

| CTB1030 | 4395 | 2020 | 1300 | / | 480 | 3 | 3150 | / | 1550 | 750 | 2 | 1595 | 1276 | 1107 | / | 1190 | 1200 | / | 180 | / | 1675 |

| CTB1218 | 3380 | 2500 | 1655 | 300 | 499 | 2 | 2600 | 690 | 1050 | 750 | 2 | 1930 | 1445 | 1343 | 1260 | 1442 | 1359 | 565 | 240 | 328 | 350 |

| CTB1224 | 3980 | 2500 | 1655 | 300 | 499 | 2 | 2900 | 690 | 1200 | 675 | 2 | 1930 | 1445 | 1343 | 1410 | 1442 | 1359 | 565 | 240 | 328 | 350 |

| CTB1230 | 4580 | 2500 | 1655 | 300 | 499 | 3 | 3500 | 690 | 900 | 650 | 3 | 1930 | 1445 | 1343 | 1710 | 1442 | 1359 | 565 | 240 | 328 | 350 |

| CTB1236 | 5180 | 2500 | 1655 | 300 | 499 | 4 | 4100 | 690 | 900 | 850 | 4 | 1930 | 1445 | 1343 | 2010 | 1442 | 1359 | 565 | 240 | 328 | 350 |

| CTB1240 | 5630 | 2500 | 1655 | 300 | 499 | 4 | 4500 | 690 | 820 | 1000 | 5 | 1930 | 1445 | 1343 | 2210 | 1442 | 1359 | 565 | 240 | 328 | 350 |

| CTB1245 | 6080 | 2500 | 1655 | 300 | 499 | 4 | 5000 | 690 | 920 | 1060 | 5 | 1930 | 1445 | 1343 | 2460 | 1442 | 1359 | 565 | 240 | 328 | 350 |

| CTB1530 | 4510 | 2730 | 1960 | 300 | 658 | 4 | 3500 | 690 | 660 | 660 | 4 | 2250 | 1620 | 1650 | 1710 | 1615 | 1665 | 560 | 230 | 304 | 1500 |

| CTB1540 | 5510 | 2730 | 1960 | 300 | 658 | 4 | 4500 | 690 | 935 | 1000 | 4 | 2250 | 1620 | 1650 | 2210 | 1615 | 1665 | 560 | 230 | 304 | 2700 |

| CTB1545 | 6380 | 2730 | 1960 | 300 | 658 | 4 | 5220 | 690 | 1060 | 1150 | 4 | 2250 | 1643 | 1650 | 2540 | 1615 | 1665 | 660 | 230 | 324 | 3000 |

| CTB1550 | 6880 | 2730 | 1960 | 300 | 658 | 5 | 5720 | 690 | 920 | 1200 | 5 | 2250 | 1643 | 1650 | 2740 | 1615 | 1665 | 660 | 230 | 324 | 3000 |

| CTB1824 | 4170 | 3115 | 2300 | 337 | 767 | 3 | 2980 | 755 | 690 | 675 | 3 | 2670 | 1890 | 1780 | 1490 | 1850 | 1960 | 685 | 300 | 324 | 350 |

| CTB1830 | 4790 | 3115 | 2300 | 337 | 767 | 4 | 3580 | 755 | 700 | 660 | 4 | 2670 | 1890 | 1780 | 1660 | 1850 | 1960 | 685 | 300 | 338 | 350 |

| CTB1840 | 5998 | 3070 | 2300 | 337 | 767 | 3 | 4720 | 755 | 1000 | 1200 | 4 | 2690 | 1916 | / | 2290 | / | 1960 | 685 | 360 | 338 | 2220 |

| CTB1850 | 7480 | 3070 | 2260 | 337 | 765 | 4 | 5780 | 755 | 900 | 1200 | 5 | 2500 | 2068 | / | 2790 | / | 1960 | 860 | 360 | 338 | 3600 |