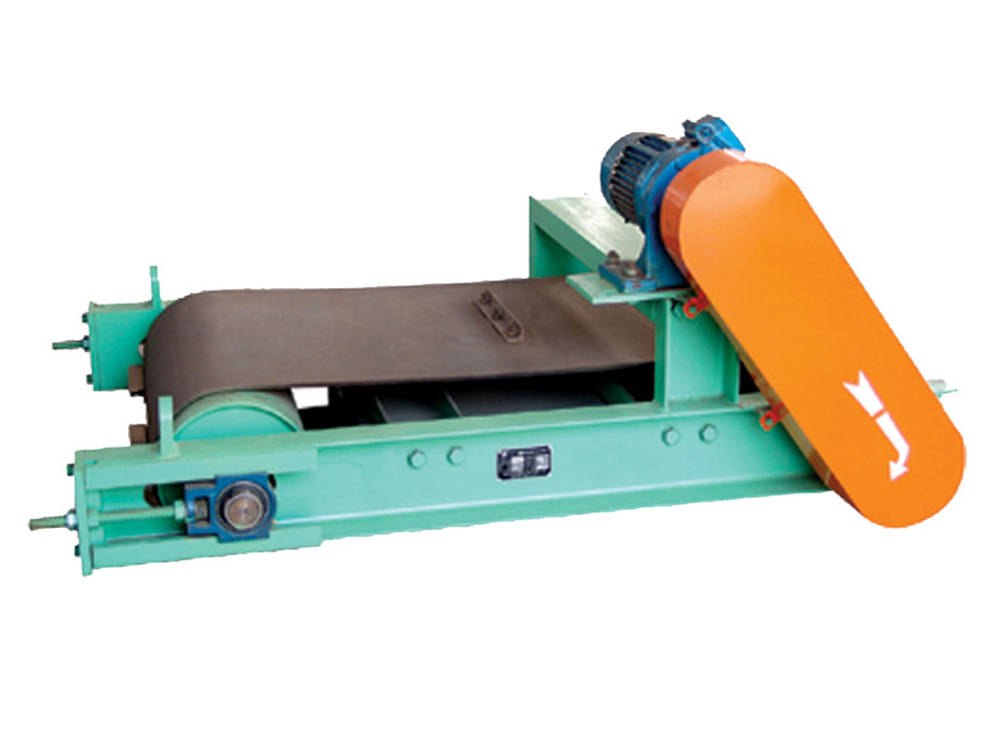

CTF Powder Ore Dry Magnetic Separator

Application

Adapted for particle size 0 ~16mm, grade between 5% to 20% of low grade magnetite and dry powder ore for pre- separation. Improve the feed grade for the grinding mill and reduce the m ineral processing cost.

Working Principle

The magnetite ore will be attracted onto the surface of drum by the magnetic force and rotated along with the drum shell to the non-magnetic area to be discharged by the gravity while the non- magnetic impurities and low-grade iron ore will be discharged from the outlet tailings directly by centrifugal force and gravity.

Technical Features

◆ Adopt small pole pitch and multi-pole magnetic system design to increase the number of magnetic flips and facilitate the discharge of miscellaneous stone.

◆ 180° large wrapping angle design effectively extends the length of the sorting area and improves the recovery rate of iron ore.

◆ The surface of the drum is made of wear-resistant ceramics with a hardness of HRA ≥ 85 and can reach a maximum of HRA92 or above. It has superior properties that cannot be replaced by other wear-resistant metal materials.

◆ Simple material distribution structure can more conveniently control the grade of concentrate and tailings.

Main Technical Parameters