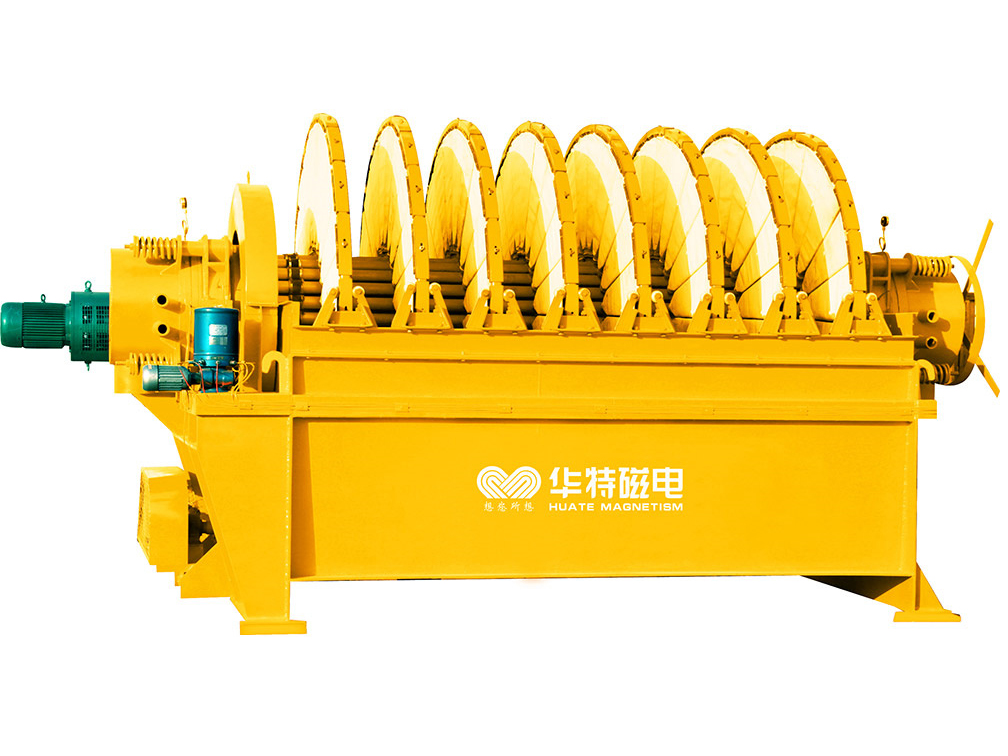

HTRX Intelligent Sensor Based Sorter

HTRX Intelligent Sensor Based Sorter

It is used for large-size dry separation of coal and coal gangue, replacing traditional manual picking. Manual picking has problems such as low picking rate of gangue, poor working environment for manual workers, and high labor intensity. The intelligent dry sorter can remove most of the gangue in advance, reduce the labor intensity of workers, reduce the power consumption and wear of the crusher, greatly reduce the amount of ineffective washing entering the main washing system, reduce the sludge of gangue and the load of the slime water system, and effectively improve and stabilize the quality of raw coal for washing, and reduce the cost of coal preparation.

The HTRX sorter system is simple, small in size, meets the requirements of explosion-proof and coal safety as a whole, and does not require water, medium, or slime water treatment. Therefore, the HTRX intelligent sorter can be easily applied in the underground, which is convenient for underground backfilling of coal gangue and reduces the cost of backfilling of coal gangue.

Working Principle

HTRX intelligent sorter is a coal gangue intelligent sorting equipment independently developed by our company. It is a subversive innovation to the mineral processing technology that has not changed for more than a hundred years. HTRX sorter is an intelligent dry sorting equipment whose sorting accuracy exceeds that of water washing (jigging) and which operates stably for a long time in the coal mining industry.

HTRX intelligent sorter adopts intelligent identification method to establish an analysis model suitable for different coal quality characteristics, through big data analysis, digitally identify coal and gangue, and finally discharge gangue through the intelligent gangue discharge system. HTRX intelligent dry sorting system includes several main systems of feeding, distributing, identification, and execution, as well as auxiliary systems such as air supply, dust collection, power distribution, and control.

Technical Characteristics Of Intelligent Sorter

01 Accurate Identification

There are corresponding equipment products in the entire wavelength range from AC waves to

electromagnetic waves of gamma rays, so that the best sensor based technology or the best combination can be selected for the mineral properties and sorting tasks to achieve the purpose of accurate identification.

02 High Speed

About 40,000 pieces of ore can be detected per second; the detector can measure 1 million spectra per second; it only takes a few milliseconds from the irradiation of the probe to the final decision whether to change the trajectory of the ore block. It also takes only a few milliseconds for a compressed air nozzle to complete 1 ejection of the ore block.

03 Large Production Capacity

About 40,000 pieces of ore can be detected per second; the detector can measure 1 million spectra per second; it only takes a few milliseconds from the irradiation of the probe to the final decision whether to change the trajectory of the ore block. It also takes only a few milliseconds for a compressed air nozzle to complete 1 ejection of the ore block.

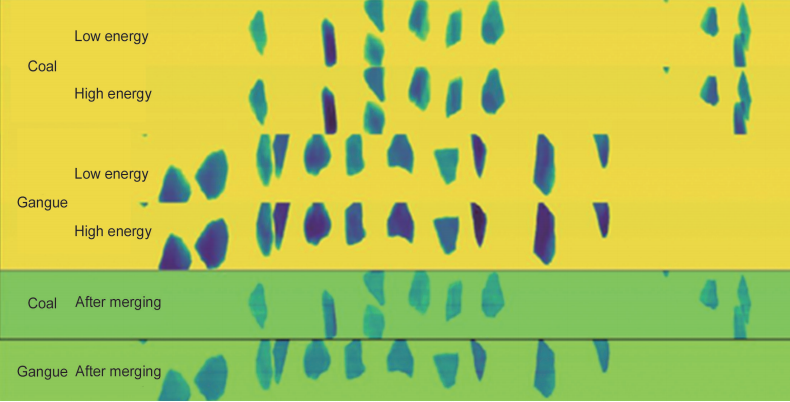

04 X-ray Imaging Example

About 40,000 pieces of ore can be detected per second; the detector can measure 1 million spectra per second; it only takes a few milliseconds from the irradiation of the probe to the final decision whether to change the trajectory of the ore block. It also takes only a few milliseconds for a compressed air nozzle to complete 1 ejection of the ore block.

Sorting Of Coal Gangue

HTRX intelligent sorter uses dual-energy segment X-ray transmission and image recognition technology, adopts advanced AI algorithm, and is equipped with high-pressure injection device to achieve precise separation of coal and gangue. In coal washing plants, it can replace lump coal jigging and heavy medium coal washing to directly produce clean coal and reduce production costs; under the coal mine, the sorter can remove the gangue from the lump coal, and the gangue can be directly buried to save the lifting cost.

X-ray Imaging Example

Advantages Of HTRX Intelligent Sorter

■Replace manual picking

The manual picking has problems such as low picking rate of gangue, poor working environment and high labor intensity for manual picking workers. HTRX intelligent sorter is used instead of manual picking, which frees manual picking workers from the harsh working environment and heavy physical labor, improves the level of intelligence, and at the same time can remove most of the gangue in advance, reducing the power consumption and loss of the crusher, and reducing the gangue sludge and coal slime water system load, improving the quality of raw coal for washing.

■Replace moving jigger

In the actual production, there are the following problems in the discharge of gangue by the moving jigger: With the increase of output and the amount of gangue in many coal preparation plants, the processing capacity of the moving jigger is seriously insufficient.

When the content of gangue is high, the wear of the moving jigger is serious and the failure rate of the equipment is high.The sorting effect of moving jigger is not good, the rate of coal carrying in gangue is high, and the loss of coal is serious.

Using HTRX intelligent sorter instead of manual picking can effectively solve the above problems, specifically: HTRX intelligent sorter has a large processing capacity, which can solve the problem of insufficient processing capacity of moving jigger. The maximum processing capacity of HTRX single equipment is 380t/h, and a single system can be matched with 8.0Mt/a coal preparation plant.

HTRX intelligent sorter can flexibly adjust "blowing coal" or "blowing gangue" according to the coal quality. When there is less gangue, HTRX conducts "blowing gangue"; when there is more gangue, HTRX can reverse the sorting of "blowing coal". The direct sorting and reverse sorting can be switched flexibly, "whoever is less will be blown", to solve the problems of poor sorting effect and serious wear of moving jigger when the content of gangue is large.