HCT DRY POWDER ELECTRO MAGNETIC IRON REMOVER

Application

It is mainly used to remove magnetic substances in battery materials,ceramics, carbon black, graphite, flame retardants, food, rare earth polishing powder, photovoltaic materials, pigments and other materials.

Working Principle

When the excitation coil is energized, a strong magnetic field is generated at the center of the coil, which induces the magnetic matrix in the sorting cylinder to generate a high gradient magnetic field. When the material passes through, the magnetic material is absorbed by the magnetic matrix, thereby obtaining high-purity concentrate;After working for a period of time, when the adsorption capacity of the matrix reaches saturation, the feeding is stopped,the distributing valve automatically turns to the iron discharge port,and the excitation coil is powered off to demagnetize the matrix,at the same time, the vibrating motor increases the amplitude,and the magnetic materials are discharged smoothly. The entire sorting process can be automatically run through program settings.

Technical Parameters

| Model | Empty core field strength Thermal | Working field strength Hot state | Sorting chamber inner diameter | Ternary precursor | Lithium carbonate Lithium hydroxide | Graphite | Iron Phosphate Lithium iron phosphate | Equipment weight | Excitation power | Total height | |

| Gauss | Gauss | mm | kg/h | kg/h | kg/h | kg/h | kg | kW | mm | ||

| HCT 150-3500 | 3500 | 14000 | 150 | 150 ~ 300 | 150 ~ 300 | 150 ~ 300 | 150 ~ 300 | 2465 | 6.8 | 1800 | |

| HCT 250-3500 | 250 | 450 ~ 600 | 500 ~ 650 | 450 ~ 600 | 450 ~ 650 | 3100 | 11 | 1940 | |||

| HCT 300-3500 | 300 | 600 ~ 800 | 650 ~ 1000 | 650 ~ 1000 | 700 ~ 1000 | 4150 | 12.5 | 1960 | |||

| HCT 350-3500 | 350 | 750 ~ 1000 | 800 ~ 1300 | 800 ~ 1200 | 850 ~ 1200 | 4980 | 15 | 2180 | |||

| HCT 400-3500 | 400 | 1100~1500 | 1100 ~ 1700 | 1100 ~ 1500 | 1100~1500 | 5670 | 18 | 2310 | |||

| HCTHCT

HCT

HCT

HCT |

150-5000250-5000300-5000

350-5000 400-5000 |

5000 | 20000 | 150 | 150 ~ 300 | 150 ~ 300 | 150 ~ 300 | 150 ~ 300 | 2465 | 13

16.5

26

35

42 |

1800

1940

1960

2180

2310 |

| 250 | 450 ~ 600 | 500 ~ 650 | 450 ~ 600 | 450 ~ 650 | 3100 | ||||||

| 300 | 600 ~ 800 | 650 ~ 1000 | 650 ~ 1000 | 700 ~ 1000 | 4150 | ||||||

| 350 | 750 ~ 1000 | 800 ~ 1300 | 800 ~ 1200 | 850 ~ 1200 | 4980 | ||||||

| 400 | 1100~1500 | 1100~1700 | 1100~1500 | 1100~1500 | 5670 | ||||||

Technical Features

◆ The finite element analysis of the magnet by computer simulation technology can quantitatively calculate the distribution and size of the magnetic field, ensuring the rational design of the magnetic circuit.

◆ The exciting coil is the core component of the whole machine, which provides a stable magnetic field for the equipment. In order to ensure the rapid cooling of the heat generated by the coil, the coil adopts a three-dimensional winding structure oil channel, which doubles the heat dissipation area and is conducive to the heat convection of the transformer oil.

◆ Adopting oil-water composite cooling method, and use the large-flow oil pump to speed up the hot oil circulation to quickly take away the heat, and the coil temperature rise is low to ensure that the coil can work reliably at low temperature. The coil housing adopts a fully sealed structure, which is moisture-proof, dust-proof and corrosion-proof, and can adapt to various harsh environments.

◆ The vibrating motor applies high-frequency, low-amplitude vibration in the vertical direction to the vibrating material cylinder, which can effectively improve the passing capacity of non-magnetic materials, prevent material clogging, and increase production capacity; when unloading iron, increase the amplitude and unload iron cleanly.

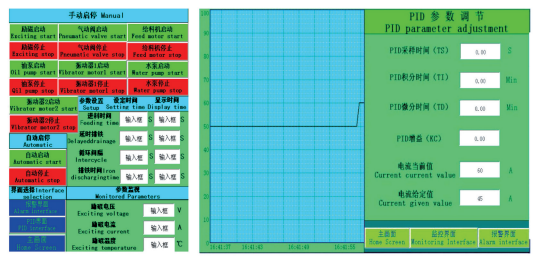

◆ The control system is equipped with advanced man-machine interface technology, and communicates with the programmable controller in real time through the Host Link bus or network cable. Through the man-machine interface, operate and monitor the equipment, and actively prompt the fault information.

◆ Collect on-site data through sensors and transmitters, and use advanced PID control theory (constant current) according to the mineral processing parameters given by the user. Regardless of whether the equipment is in a hot or cold state, the control system can quickly reach the rated excitation field strength. It solves the previous problems of reduced magnetic field strength and slow rise and demagnetization speed when the equipment is running in a hot state.

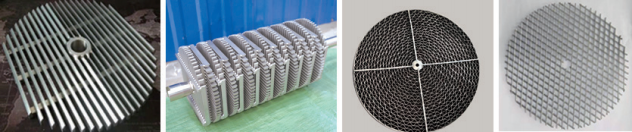

◆ The matrix is made of SUS430 magnetically conductive stainless steel. According to the material size, it can be in the form of rods, corrugated sheets and meshes. Multiple pieces of media are placed alternately, so that the materials can be fully sorted and the iron can be removed cleanly.