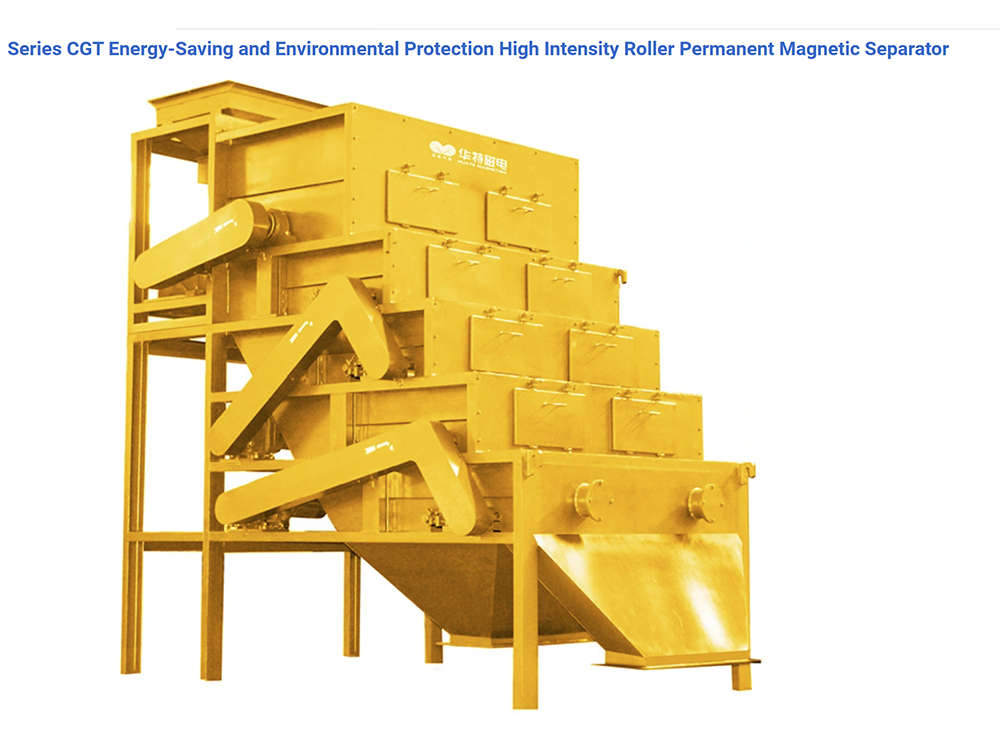

CGT series high field strength drum permanent magnet magnetic separator

Application

Removing weak magnetic impurities from granular or coarse powder materials.It can be used for the purification of non-metallic minerals such as ceramics, glass, refractory materials, as well as the purification of chemical, food, and pharmaceutical industries. It can also be used for the dry pre-selection of weakly magnetic minerals such as hematite and limonite, as well as the dry separation of manganese ore.

Technical Characteristics

◆ The reasonable combination of permanent magnet drum and permanent magnet drum can achieve better iron removal effect.

◆ The drum adopts a new type of compensated magnetic pole magnetic system, which has higher magnetic field strength and stronger suction.

◆ The magnetic system of the drum can be made into a flipping type, greatly improving the cleaning rate.

◆ The surface magnetic field of the drum can reach 8000Gs.

◆ The rotary speed of the drum and magnetic roller are adjusted through frequency conversion to meet wider particle size and production requirements.

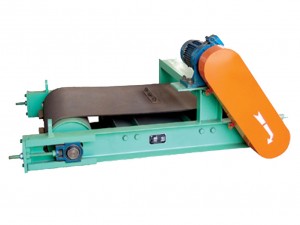

◆ The magnetic roller adopts a concentrated magnetic composite magnetic system, with a magnetic field strength of 18000Gs and a higher gradient.

◆ The conveyor belt used for the magnetic roller is made of special materials and has good wear resistance.

◆ The controllable feeding system ensures the uniformity of the material when flowing through the magnetic field area.

◆ Weak magnetic oxides can be automatically cleaned, ensuring long-term and trouble- free operation.

◆ Reserved dust removal port for centralized dust discharge, meeting environmental protection requirements.

Main Technical Parameters

| Model | Diameter × Length mm×mm |

Rotary speed r/min |

Magnetic induction intensity Gs |

Number of mag | Thickness of belt mm |

Processing capacity t/h |

Motor powerkW | ||||

| Drum | Magnetic roller | Drum | Magnetic roller | Drum | Magnetic roller | Drum | Magnetic roller | ||||

| CGT-3/5 | Φ300x500 | Φ100x500 | 30 | Variable frequency adjustable 17-82 |

≥4000 | ≥12000 | 1 | 0.1-2.0 | 0.8-1.0 | 0.75 | 0.37 |

| 2CGT-3/5 | 2 | 0.37 | |||||||||

| 3CGT-3/5 | 3 | 0.55 | |||||||||

| 4CGT-3/5 | 4 | 0.55x2 | |||||||||

| CGT-4/8 | Φ400x800 | Φ100x800 | 1 | 1.2-2.0 | 1.1 | 0.55 | |||||

| 2CGT-4/8 | 2 | 0.75 | |||||||||

| 3CGT-4/8 | 3 | 0.75 | |||||||||

| 4CGT-4/8 | 4 | 0.75x2 | |||||||||

| CGT-5/10 | Φ500x1000 | Φ100x1000 | 1 | 2.0-3.5 | 1.5 | 0.55 | |||||

| 2CGT-5/10 | 2 | 0.75 | |||||||||

| 3CGT-5/10 | 3 | 0.75 | |||||||||

| 4CGT-5/10 | 4 | 0.75x2 | |||||||||

| CGT-5/12 | Φ500x1200 | Φ100x1200 | 1 | 4.0-7.0 | 2.2 | 0.75 | |||||

| 2CGT-5/12 | 2 | 1.1 | |||||||||

| 3CGT-5/12 | 3 | 1.1 | |||||||||

| 4CGT-5/12 | 4 | 1.10x2 | |||||||||

| CGT-6/15 | Φ600x1500 | Φ100x1500 | 1 | 7.0-10.0 | 4 | 0.75 | |||||

| 2CGT-6/15 | 2 | 1.5 | |||||||||

| 3CGT-6/15 | 3 | 1.5 | |||||||||

| 4CGT-6/15 | 4 | 1.50x2 | |||||||||