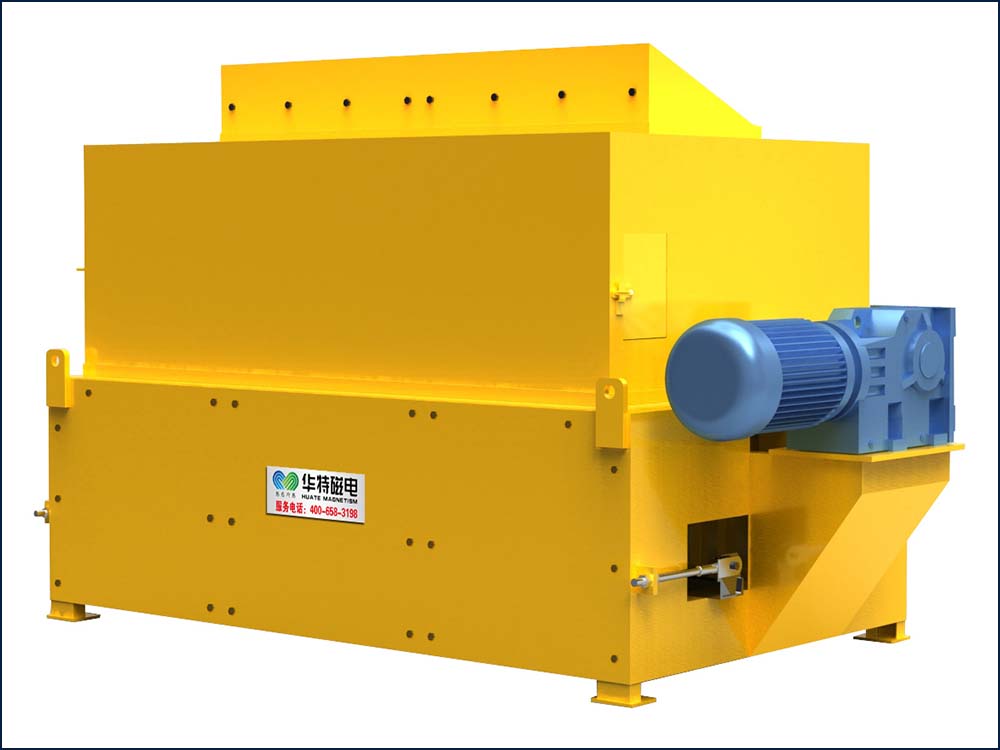

High Quality and Low Price Magnetite Ores Rotating Drum Magnetic Separator for Dry Powder and Granular Processing Industry Drum Dry Magnetic Separator

High Quality and Low Price Magnetite Ores Rotating Drum Magnetic Separator for Dry Powder and Granular Processing Industry Drum Dry Magnetic Separator,

Magnetic Magnetite Ore Separator, Powder Ore Magnetic Separator, Rotating Drum Dry Magnetic Separator,

Working principle

The magnetite ore will be attracted onto the surface of drum by the magnetic force and rotated along with the drum shell to the non-magnetic area to be discharged by the gravity while the non-magnetic impurities and low-grade iron ore will be discharged from the outlet tailings directly by centrifugal force and gravity.

Application site

Applicable Scope:

This machine is used for beneficiation of 5~20% low grade magnetite with particle size 0~16 mm, and for pre-separation of fine magnetite ores. It can improve the grade of feed materials for the grinding mill and reduce the mineral processing costs.

The magnetite ore will be attracted onto the surface of drum by the magnetic force and rotated along with the drum shell to the non-magnetic area to be discharged by the gravity while the non-magnetic impurities and low-grade iron ore will be discharged from the outlet tailings directly by centrifugal force and gravity.

1. Adopt the multi-magnetic pole arrangement with short distances between poles in the internal magnetic system, which can increase the stirring of the magnetic particles and remove the gangues from minerals.

2. 180° broad-angle magnetic system can effectively prolong the separation area, and improve the recovery of iron ores.

3. Wear-resistant ceramics are stuck on the drum surface, the hardness HRA is ≥85, maximum HRA92.

4. Simple material distribution device, which can conveniently control the grade of the concentrate and the tailing.

FAQ:

Q:Factory or Trading company?

A:Shandong Huate Magnet is a factory was established in1993.

Q:Factory Address?

A: Our factory is located in Huate Road, Linqu County, Shandong Province, China. Welcome to visit us!

Q: About Quotation?

A: Before quotation, we need confirm the Belt width, Magnetic field intensity, Material size and Quantity, all of these factors will affect the price.

Q:Quality control?

A: Our factory have passed ISO9001 and CE certifications.

If you have any question please promptly chat with me or leave me a message, I will contact you within one business day. If you like to be contacted please leave your email address or cell phone number to me. Looking forward to your inquiry.