High Performance China Permanent Magnetic Iron Separator, Magnet Separator, Iron Separator for Agreggate Site

We are convinced that with joint efforts, the business between us will bring us mutual benefits. We can assure you product quality and competitive price for High Performance China Permanent Magnetic Iron Separator, Magnet Separator, Iron Separator for Agreggate Site, Hope we are able to produce a far more superb long term with you by our efforts from the foreseeable future.

We are convinced that with joint efforts, the business between us will bring us mutual benefits. We can assure you product quality and competitive price for China Magnet Separator, Magnetic, We warmly welcome your patronage and will serve our clients both at home and abroad with goods of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Features

The deformation shell rotates for the magnetic system, which increases the structure of the magnetic system from the structure.

Material separation is more thorough. Use high temperature resistance. Strong magnetic NdFe magnetic material, high magnetic field strength, the whole machine is connected in series to the powder conveying pipe.

Medium and flange connection, easy installation. Iron removal and iron removal are done automatically. The equipment does not require special care, and the permanent magnet is used as the magnetic source.

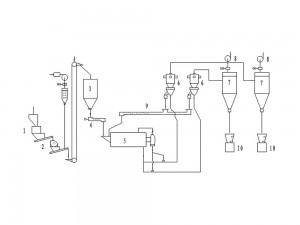

No power consumption, low power, low electrode consumption, compact structure, stable and reliable.Mainly used in the cement industry:The regrind coarse powder after powder selection by the classifier and the fine powder before the clinker is pre-crushed to remove iron to prevent iron particles from accumulating in the mill, thereby improving the production efficiency of the mill and the specific surface area of the cement;The iron removal before the cement filling process can automatically clean and discharge the iron impurities mixed in the cement to ensure the stable operation of production.

1.The rotation of the deformed shell is the operation of the magnetic system, which increases the action process of the magnetic system from the structure. Equipped with a unique separation mechanism, the iron debris can be separated more thoroughly.

2.Adopt high-temperature resistant, strong magnetic NdFeB magnetic material, high magnetic field strength. The whole machine is connected in series in the powder conveying pipeline, flanged connection, easy to install.

3.Iron removal and unloading are automatically completed, and the operation of the equipment does not need to be supervised.

4.Permanent magnets are used as magnetic sources, no electricity consumption, low-power electric slag discharge, low electrode consumption, compact structure, stable and reliable work.