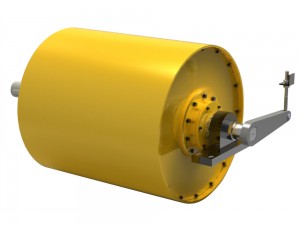

CTDG Series Permanent Magnet Dry Large Block Magnetic Separator

This machine is a new type of high-efficiency energy-saving mineral processing equipment. Magnetic separators (magnetic pulleys) with different magnetic induction intensities and suitable for different belt specifications can be designed and manufactured according to the specific requirements of users. The products are widely used in metallurgy and other industries, and can meet the needs of large, medium and small mines. They are used in pre-selection operations in various stages after crushing in magnetic separation plants to remove mixed waste rocks and restore geological grade, which can save energy consumption. It is used to increase the processing capacity of dressing plants; it is used in stopes to recover magnetite ore from waste rock and improve the utilization rate of ore resources; it is used to recover metallic iron from steel slag; it is used in garbage disposal to sort useful metals and improve the environment.

Technical Features

◆ The magnetic system is made of NdFeB material with strong magnetic force, large magnetic penetration depth, high remanence and high coercive force, ensuring a high magnetic field intensity on the surface of the drum. The magnetic system is covered with stainless steel protection to ensure that the magnet block will never falloff.

◆ The drum body is made of high-quality stainless steel, which can not only improve the wear resistance of the drum, but also extend the service life of the drum, and is suitable for various harsh environments.

◆ Non-magnetic stainless steel is used between the drum main shaft and the magnetic system to ensure that there is no magnetic leakage transmitted to the main shaft, thereby ensuring the smooth operation of the bearing.

Main Technical Parameter

| Model | Drum diameter mm | Drum lenght mm |

Belt width mm |

Magnetic inductionintensityof drum surface mT | particle size mm |

Capacity t/h |

Weight t |

| CTDG-50/50 | 500 | 600 | 500 | 160-350 | ≤ 50 | 50-80 | 0.4 |

| CTDG-50/65 | 500 | 750 | 650 | 160-350 | ≤ 50 | 60-110 | 0.5 |

| CTDG-63/65 | 630 | 750 | 650 | 160-400 | ≤ 50 | 70-120 | 0.8 |

| CTDG-50/80 | 500 | 950 | 800 | 160-400 | ≤ 50 | 70-150 | 0.6 |

| CTDG-63/80 | 630 | 950 | 800 | 180-500 | ≤ 150 | 100-160 | 0.9 |

| CTDG-80/80 | 800 | 950 | 800 | 180-500 | ≤ 150 | 120-200 | 1.2 |

| CTDG-63/100 | 630 | 1150 | 1000 | 180-500 | ≤ 150 | 130-180 | 1.4 |

| CTDG-80/100 | 800 | 1150 | 1000 | 180-500 | ≤ 150 | 150-260 | 1.6 |

| CTDG-100/100 | 100 | 1150 | 1000 | 180-500 | ≤ 250 | 180-300 | 2.6 |

| CTDG-63/120 | 630 | 1400 | 1200 | 180-500 | ≤ 150 | 150-240 | 1.5 |

| CTDG-80/120 | 800 | 1400 | 1200 | 180-500 | ≤ 150 | 180-350 | 2.5 |

| CTDG-100/120 | 1000 | 1400 | 1200 | 180-500 | ≤ 250 | 200-400 | 3.1 |

| CTDG-120/120 | 1200 | 1400 | 1200 | 180-500 | ≤ 250 | 220-450 | 4.5 |

| CTDG-80/140 | 800 | 1600 | 1400 | 180-500 | ≤ 250 | 240-400 | 3.7 |

| CTDG-100/140 | 1000 | 1600 | 1400 | 180-500 | ≤ 250 | 260-450 | 4 |

| CTDG-120/140 | 1200 | 1600 | 1400 | 180-500 | ≤ 300 | 280-500 | 4.6 |

| CTDG-140/140 | 1400 | 1600 | 1400 | 180-500 | ≤ 350 | 300-550 | 5.5 |