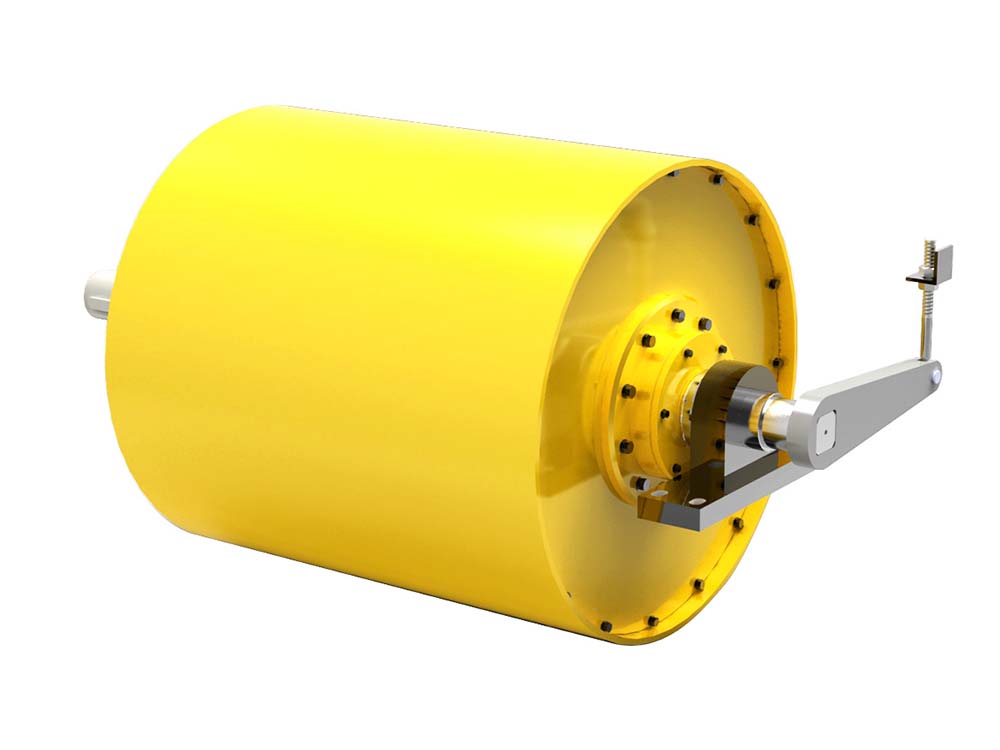

Low MOQ for Wet Roller Magnetic Separator With High Magnetic Intensity - Dry Powder Electromagnetic Separator – Huate

Low MOQ for Wet Roller Magnetic Separator With High Magnetic Intensity - Dry Powder Electromagnetic Separator – Huate Detail:

Features

◆The magnetic circuit adopts computer simulation design with scientific and rational magnetic field distribution.

◆Both ends of the coils are wrapped by steel armor to raise the utilizing rate of magnetic energy and increase the magnetic field intensity in the separation area by more than 8%, and the background magnetic field intensity can reach 0.6T.

◆The shell of excitation coils are in wholly sealed structure, moisture, dust and corrosion proof, and can work in harsh environments.

◆Adopting oil-water compound cooling method. The excitation coils have fast heat radiating speed, low temperature rise and small thermal reduction of magnetic field

◆Adopting magnetic matrix made of special materials and in different structures, with large magnetic field gradient and good iron removal effect.

◆Vibration method is adopted in the iron removal and discharge processes to prevent material blockage.

◆Material barrier is set up in the material division box to solve the material leakage around the flap plate for clear iron removal.

◆The shell of the control cabinet is made of high quality steel plate and with structure of double layer door. It is dust-proof and water-proof with IP54 rating.

◆The control system adopts programmable controller as the core control component to control each actuating mechanism so that they run in accordance with the process flow cycle with high automation level.

Application site

Product detail pictures:

Related Product Guide:

Our personnel are always inside the spirit of "continuous improvement and excellence", and together with the outstanding excellent goods, favorable price and good after-sales services, we try to gain every customer's trust for Low MOQ for Wet Roller Magnetic Separator With High Magnetic Intensity - Dry Powder Electromagnetic Separator – Huate, The product will supply to all over the world, such as: Montpellier, Tajikistan, Mali, Our Company has qualified engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the items, Be sure to feel free to contact us.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.