High Quality Magnetic Separator Powder - Process flow of Quartz sand Production Line – Huate

High Quality Magnetic Separator Powder - Process flow of Quartz sand Production Line – Huate Detail:

Technical parameters

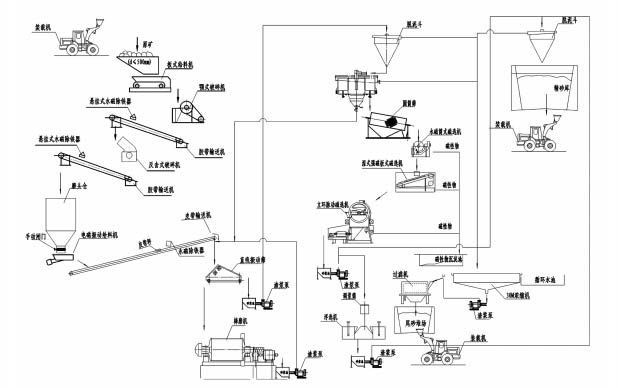

Firstly, Quartz fall under the hopper,quartz stone is broken into the coarse material after primary crushing, and be transported by belt conveyor for further crushing to the second crushing machine, then the smaller stone will be taken into the vibrating screen for screening out two type size quartz stones, exceed size stone will be returned to crushing machine again. Sieved material into the rod milling machine, Materials from the rod milling machine to classify through the cylinder screen. in the sieve to return to the rod milling machine, Sieved material to eliminate the tramp iron by high intensity magnetic separator, and then into the Vertical Ring High Gradient Magnetic Separator to remove the residual mechanical iron and associated iron , usually after two procedures of separating, quartz sand iron content can down to below 0.07%, Finally ,the qualified pulp through the hydraulic desliming slot to take off the mud, and then dehydrated to become the qualified quartz sand products.

In the production line, Rod mill and the High Gradient Magnetic Separator is one of the core equipment, this production line is a high degree of automation, low operation cost, high crushing efficiency, energy saving, large output, less pollution, easy maintenance, the final quartz sand has the uniform size, good grain shape and reasonable size distribution, which can meet the national standards of construction machine-made sand.

Processing Chart

Raw ore → crushing (coarse crushing, medium crushing and fine crushing) → pre screening and inspection → ore washing → rod grinding → classification → dehydration → weak magnetic separation → strong magnetic separation → classification → dehydration → end product

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for High Quality Magnetic Separator Powder - Process flow of Quartz sand Production Line – Huate, The product will supply to all over the world, such as: Kuwait, Milan, Amman, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.