Best-Selling Pipeline Magnetic Separator - TCTJ Desliming & Thickening Magnetic Separator – Huate

Best-Selling Pipeline Magnetic Separator - TCTJ Desliming & Thickening Magnetic Separator – Huate Detail:

Separating and desliming for overflow product of classification after first grinding. Pulp thickening before the second grinding and filtering.

The magnetic mineral’s desliming before feeding into the fine screen and reverse flotation; the final concentration of magnetite.

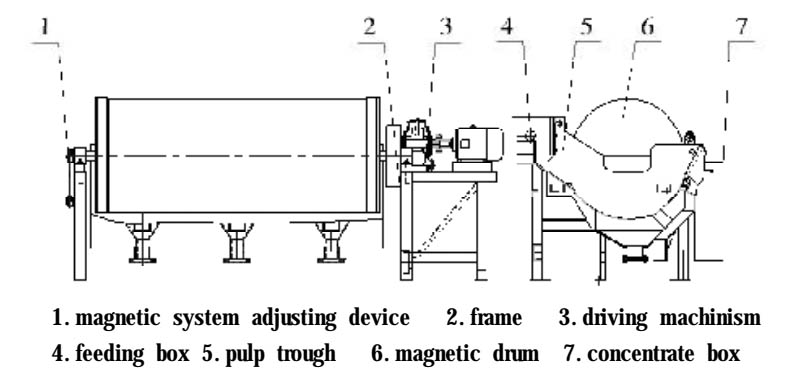

Structure

Working principle

After the pulp is fed into the feed box,it can be fed into separation area directly.The magnetic mineral is absorbed on the surface of the magnetic drum after magnetization and transferred to mineral unloading area forehead by the rotative separation drum.Under the washing water pushing ,it can deslime the tailings and the mineral is discharged into the concentrate box with the washing water or scraper ,it becomes the concentrate.Meanwhile ,the nonmagnetic mineral in pulp flows into the the bottom box with the pulp .Due to the difference of the particles size and the density in the bottom box,it can make the heavy and coarse particles sink to the bottom and out from the tailing mouth ,then this is the coarse tailing , the light slime can be discharged by the overflow devices.

Patent technological innovation point 1

Concentrated magnetic separator is equipped with Multipoint feeding flange in the feeder box,open top design can achieve side and top feed, there is overflow weir in the feeding box, which makes the materials in tank are uniform in the direction of drum length.

Patent technological innovation point 2

The magnetic field strength and depth of the drum surface can be adjusted by adjusting the magnetic system structure according to the material properties and separation targets, which makes the magnetic materials in tailings in less than 0.5% compared with common magnetic separators.

Patent technological innovation point 3

The magnetic system is divisionally designed according to the separation target,to enhance the magnetic strength in scarenging area, concentration area adopting multi-pole structure to reduce magnetic materials in tailing, improve the recovery and concentrate grade.

Patent technological innovation point 4

Magnetic system wrap angle is 160°larger than 127°of the normally downstream type,magnetic separation area is lengthened and magnetic materials roll times are increased, the concentrate grade is improved.

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for Best-Selling Pipeline Magnetic Separator - TCTJ Desliming & Thickening Magnetic Separator – Huate, The product will supply to all over the world, such as: Cancun, Macedonia, Brisbane, With the intensified strength and more reliable credit, we are here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We will endeavor to maintain our great reputation as the best products supplier in the world. If you have any questions or comments, please contact with us freely.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.