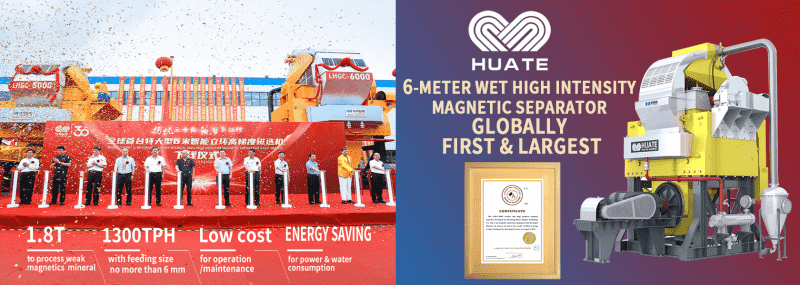

The World’s Largest and Latest Generation Magnetic Separator Rolled Off Production Line at Huate Magnet Group in China

World’s leading magnetic separation equipment supplier, Huate Magnet Group, renowned for its 30 years of expertise, has recently unveiled a remarkable achievement: the completion of the world’s largest vertical ring Wet High Gradient Magnetic Separator (LHGC6000-WHIMS).

As a professional innovation group, Huate has successfully launched the brand new intelligent magnetic separator by solving several long-standing technical challenges, including large-scale coil heat dissipation, transportation of oversized and overweight components, and automatic detection of key components.

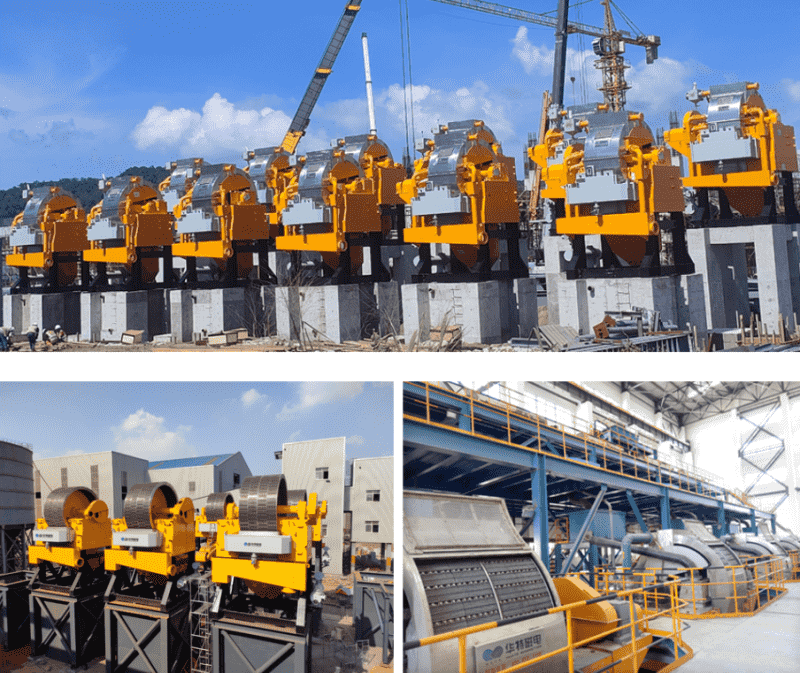

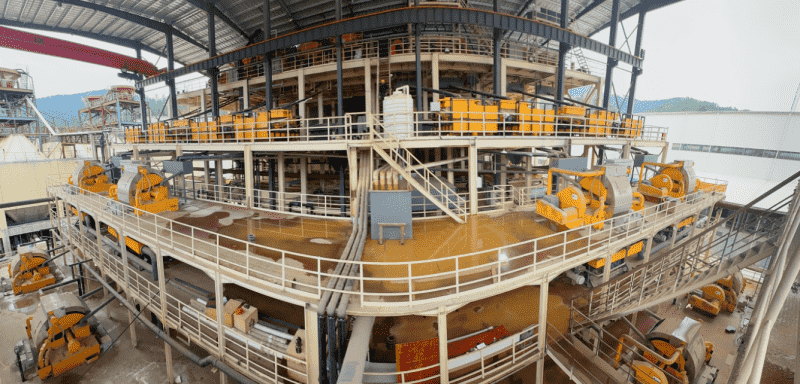

The LHGC–6000 WHIMS has its core ring component with a diameter of 6 meters, standing at an equipment height of 11.8 m and weighting 700t. With a background field strength from 0 to 1.8 Tesla, it can process up to 1,300 t/h hematite and up to 800 t/h quartz sand–8 times the capacity of the 3-meter WHIMS. Moreover, it significantly reduces energy consumption by over 60% per ton of processed ore, thus effectively cutting operational costs. It optimizes space utilization per ton of ore output, leading to simplified process layouts and more than 30% savings in engineering investments. It meets the demand for extra-large equipment of large-scale mining enterprises with an output of tens of millions of tons.

The oil–cooled external circulation for heat dissipation is adopted for the excitation coil. Split structure and modular assembly are incorporated for the extra–large components such as the vertical ring. Intelligent operational functions include automatic liquid level adjustment, real-time pressure and temperature detection with alarm capabilities, and automated lubrication. The integration of Internet of Things and big data analysis technologies enables remote operation, fault diagnosis, and comprehensive life cycle management.

The LHGC-6000 WHIMS holds immense potential in the separation of weak magnetic minerals, including iron oxide, titanium, manganese, chromium, cobalt, and rare earth minerals. It also excels in removing iron and impurities from non-metallic minerals like quartz and feldspar. Huate Magnet has deployed more than 2,200 WHGMS globally, accumulatively contributing over $10 billion USD in social benefits.

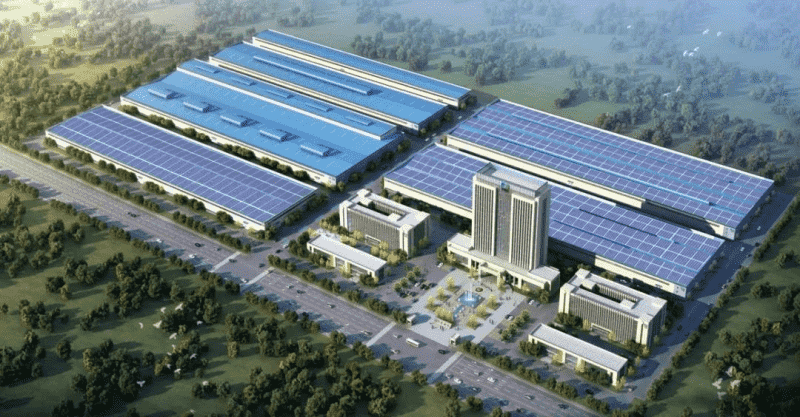

Founded in 1993, Huate Magnet Group is headquartered in Weifang, China, encompassing a vast 270,000 square meters of plant area and employing over 1,000 skilled professionals. Huate Magnet specializes in manufacturing superconducting magnetic separator, electromagnetic and permanent magnetic separator, slurry magnetic stirrer, ultra-fine grinding and classifying equipment, mining complete set equipment, medical magnetic resonance imaging (MRI) etc. In addition, Huate Mineral Processing Design Institute has provided metallic and non-metallic mineral processing line EPC+M&O services in Germany, Malaysia, Vietnam and beyond. In order to provide better services, Huate has established intelligent mineral processing laboratories in Germany, Australia, South Africa, and so on. With more than 20,000 customers, Huate’s products reach corners of the world, including USA, Germany, Australia and beyond.

next step, Huate Magnet will give full play to its technological leadership in the field of mineral processing, focusing on the research on mineral processing technology and equipment, continuously break through the “bottleneck” technology, and lead the large-scale, intensive, intelligent, and green and low-carbon development of mining equipment.

Post time: Sep-01-2023