The comprehensive utilization of tailings is a hot word in the mining field in recent years, and research on the comprehensive utilization of gold tailings has also been carried out. It is understood that the production of gold mine tailings in my country has reached more than 1.5 billion tons, but the comprehensive utilization rate is less than 20%.At present, the most ideal way to realize the waste-free and harmless disposal of gold mine tailings includes two ways: underground filling and resource utilization.The traditional filling process of gold mines is to fill the coarse-grained tailings into the well, while the fine-grained tailings are piled up in the tailings pond.Because the content of gold ore is usually low, in order to maximize the acquisition of gold resources, it is usually necessary to carry out grinding operations. Therefore, the fine-grained tailings contain a lot, while the coarse-grained tailings are less, and only the coarse-grained tailings are filled underground. , it is impossible to fundamentally reduce solid waste and reduce the storage capacity of tailings ponds. Retaining tailings ponds still requires a lot of land and harms the environment.The disposal of gold tailings has become a major factor restricting the sustainable economic development of gold mines.

On February 10, 2022, the Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Science and Technology, the Ministry of Finance, the Ministry of Natural Resources, the Ministry of Ecology and Environment, the Ministry of Commerce, and the State Administration of Taxation jointly issued the “On Printing and Distributing Accelerating the Promotion of Industrial Resources”. The “Notice on the Implementation Plan for Comprehensive Utilization” requires that by 2025, the intensity of industrial solid waste generation in key industries such as iron and steel, non-ferrous metals, and chemical industries in my country will decrease, the comprehensive utilization level of bulk industrial solid waste will be significantly improved, the renewable resource industry will continue to develop healthily, and industrial resources will be comprehensively utilized. Efficiency has been significantly improved, and the comprehensive utilization rate of bulk industrial solid waste will reach 57%.Therefore, the resource utilization of gold tailings is imperative.

The Sino-German Key Laboratory of Magnetoelectricity and Intelligent Mineral Processing of Huate Company conducts a large number of beneficiation experiments on the gold tailings in Yantai area. The main mineral components of the gold tailings are gangue minerals such as quartz, feldspar and calcite, and a small amount of mechanical Iron, magnetic iron, iron oxide, titanium oxide, iron silicate, iron sulfide and other impurities.The particle size range of gold tailings is generally 200 mesh 50-70%, the particle size is relatively uniform, and it contains a small amount of fine mud. The main impurity Fe2O3 content is 1-3%, TiO2 content is 0.1-0.3%, CaO content is 0.12-1.0%, and the whiteness of gold tailings is 5-20%. There are certain differences in the composition of tailings produced by different concentrators. Some tailings have high SiO2 content, or contain spodumene, sericite, etc. Most of them belong to the feldspar-quartz type pegmatite type, with high reuse value.

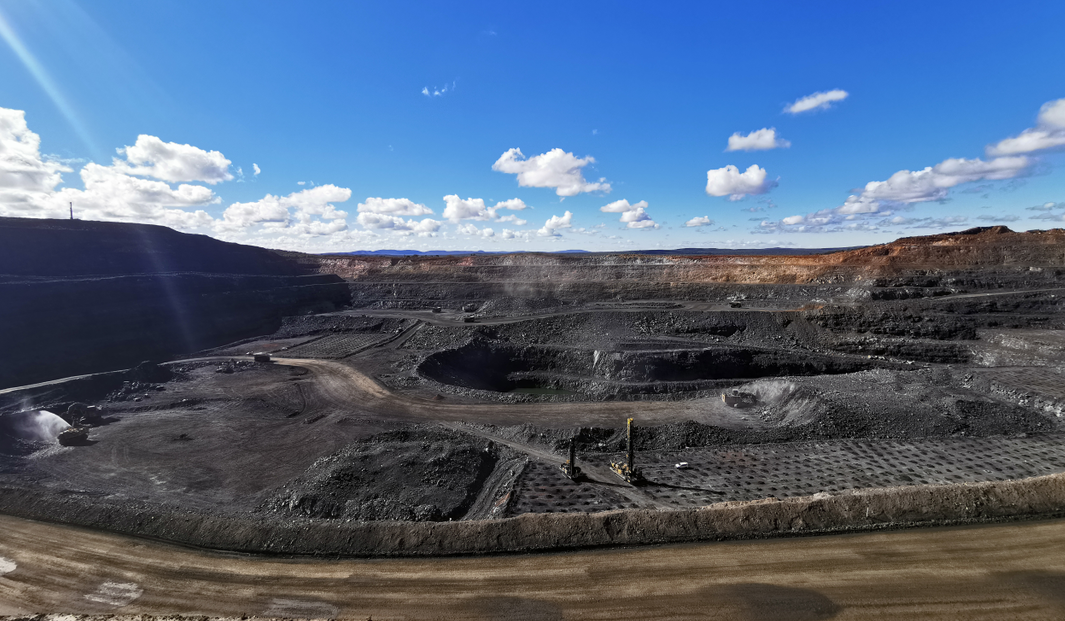

Huate Company invented the “magnetic separation-gravity separation” combined beneficiation process, and obtained the invention patent authorization in September 2020. The patent content is about “a comprehensive utilization method of gold tailings containing gold, iron and feldspar.At present, more than ten large-scale industrial applications have been carried out in Yantai, Shandong, the largest of which can process 8,000 tons of gold tailings per day.In this process, advanced beneficiation equipment such as vibrating screen, spiral chute, shaking table, drum magnetic separator, wet strong magnetic plate magnetic separator, vertical ring high gradient magnetic separator, and electromagnetic slurry magnetic separator are used in combination. While obtaining high-quality feldspar concentrate from the tailings, valuable products such as magnetite, gold-bearing minerals, cement raw materials, and brick-making raw materials are also recovered to realize the comprehensive utilization of gold tailings and achieve zero discharge in an all-round way.

Vertical ring high gradient magnetic separator and electromagnetic slurry high gradient magnetic separator are used in gold tailings project

Post time: Mar-11-2022