The sorting area of the medium field strength semi-magnetic self-unloading tailings recovery machine has a strong magnetic area, a medium magnetic area and a weak magnetic area. The polarity of the magnetic poles alternately forms a semi-circular annular magnetic system. A part of the shell is immersed in the pulp, and the magnetic particles in the pulp are continuously adsorbed by the method of continuous rotation.The magnetic particles continue to roll with the rotation of the shell, so that the non-magnetic materials in the magnetic materials are continuously washed out. There is no magnetic field in the upper right part of the semi-ring magnetic system. The material is discharged into the concentrate tank.

Features

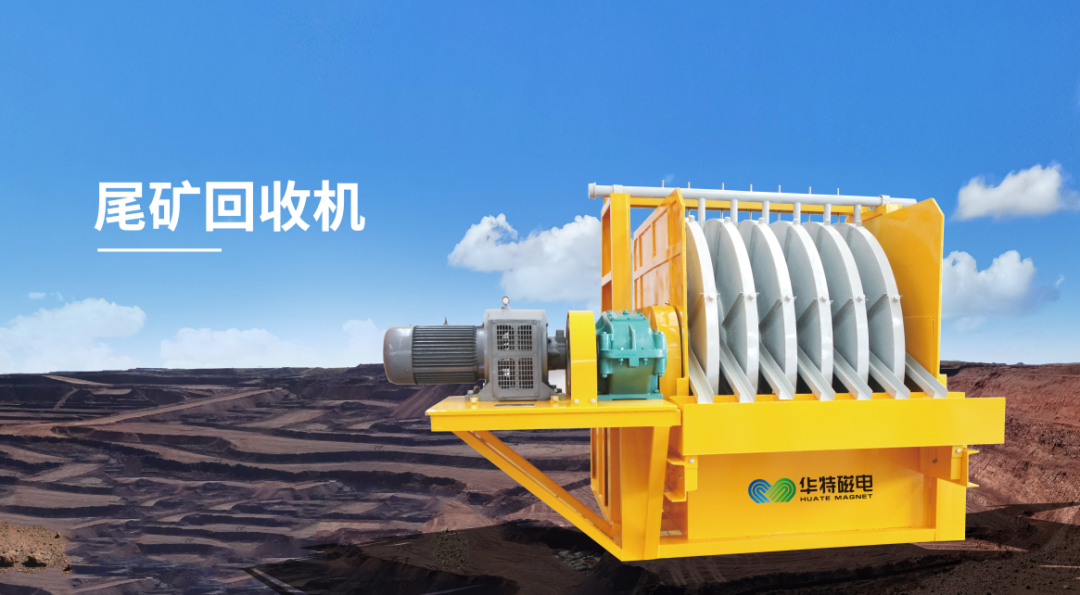

The YCBW series medium field strength semi-magnetic self-unloading tailings recovery machine produced by Huate Company has the characteristics of good sealing effect, high reliability and long service life.

In the magnetic area, multiple sets of magnetic pole pairs with opposite polarities are arranged alternately. During the rotation, the magnetic material is continuously rolled in the collecting plate and water, washed and de-sludged, so that the recovered magnetic material has a higher purity and better recovery effect.

A weak magnetic area is set between the magnetic field area and the non-magnetic area in the magnetic disk. When the magnetic material enters the non-magnetic area, it passes through the weak magnetic field transition area, and the adsorption area of the weak magnetic field area gradually decreases. The inclined deflector also prevents the magnetic material from moving back and enables quick discharge under the action of gravity and flushing water.

The belt-type transmission mode avoids the hidden danger of motor burnout due to magnetic system stall.

The electromagnetic speed regulating motor is adopted, which is easy to operate and can be operated without professionals, and the maintenance cost is low.

Application range and effect

The YCBW series medium field strength semi-magnetic self-unloading tailings recovery machine developed and produced by Huate can recover medium magnetic minerals in the slurry.

A concentrator of Anshan Iron and Steel selected 8 sets of YCBW-15-8 mid-field strength semi-magnetic self-unloading tailings recovery machines for tailings recovery. The recovery effect is as follows:

Medium field strength semi-magnetic self-unloading tailings recovery machine: the pulp processing capacity is 700-800m³/h, and the magnetic iron content of the ore is 2.3-2.5%. After being recovered by the tailings recovery machine, the magnetic iron content of the tailings is reduced to 0.5-0.7%, and the recovery effect is remarkable.

Scope of technical services of Huate Mineral Processing Engineering Design Institute

①Analysis of common elements and detection of metal materials.

②Removal and purification of non-metallic minerals such as quartz, feldspar, kaolin, bauxite, spodumene and pyrophyllite.

③Iron, titanium, manganese, chromium, vanadium and other ferrous metals beneficiation.

④ Mineral beneficiation of weak magnetic minerals such as rare earth, wolframite, tantalum-niobium, garnet and tourmaline.

⑤ Comprehensive utilization of secondary resources such as various tailings and tailings.

⑥ Nonferrous metal mineral magnetic separation + gravity separation or flotation and other joint beneficiation.

⑦Black, non-ferrous and non-metallic minerals intelligent sensor sorting.

⑧ Ultrafine powder processing such as material crushing, ball milling and grading.

⑨ Semi-industrialized selection test.

⑩ EPC turnkey projects such as crushing, pre-selection, grinding, magnetic (heavy, flotation) separation, and dry discharge of mining processing plants.

Post time: Mar-28-2022