Mica is one of the main rock-forming minerals, and the crystal has a layered structure inside, so it presents a hexagonal flake crystal. Mica is a general term for the mica group of minerals, mainly including biotite, phlogopite, muscovite, lepidolite, sericite, and lepidolite.

Ore Properties and Mineral Structure

Mica is an aluminosilicate mineral and is divided into three subgroups: muscovite, biotite and lepidolite. Muscovite includes muscovite and less commonly sodium mica; biotite includes phlogopite, biotite, manganese biotite; lepidolite is a fine scale of various mica rich in lithium oxide; sericite is a clay mineral with certain characteristics of natural fine-grained muscovite. In industry, especially in the electrical industry, muscovite and phlogopite are commonly used. The main components of mica are silicon, aluminum, potassium, magnesium, lithium, crystal water and a small amount of iron, manganese, titanium, chromium, sodium, calcium, etc. Mica has perfect cleavage and can be peeled off.Among them, biotite and phlogopite have weak magnetic properties, and other mica sheets may also be embedded with impurities such as iron and manganese and have certain weak magnetic properties. Mohs hardness is 2~3, density is 2.7~2.9g/cm3, common associated minerals are pyrite, tourmaline, beryl, feldspar, quartz, spinel, diopside, tremolite, etc., among which yellow Iron ore, tourmaline, spinel, diopside, etc. have weak magnetic properties.

Application areas and technical indicators

Muscovite has good physical and chemical properties such as high dielectric strength, high resistance, low dielectric loss, arc resistance, corona resistance, hard texture, high mechanical strength, high temperature resistance, acid and alkali resistance, so it is widely used in industry. It has a wide range of uses; the main properties of phlogopite mica are slightly inferior to muscovite mica, but it has high heat resistance and is a good heat-resistant insulating material; fragment mica refers to the general term for the fine mica that is mined and the leftovers produced by processing and tableting. ; Lepidolite, also known as phosphomica, is a mineral raw material for lithium extraction, and sericite is widely used in rubber, plastics, metallurgy, cosmetics, etc.

Processing Technology

Beneficiation and purification

The beneficiation and purification methods of mica vary according to its nature and type. Flake mica generally adopts manual sorting, friction beneficiation, shape beneficiation, etc.; crushed mica adopts wind separation and flotation, biotite and phlogopite can adopt strong magnetic separation, muscovite, lepidolite and sericite contain weak magnetic properties. Impurities can also be removed by strong magnetic separation.

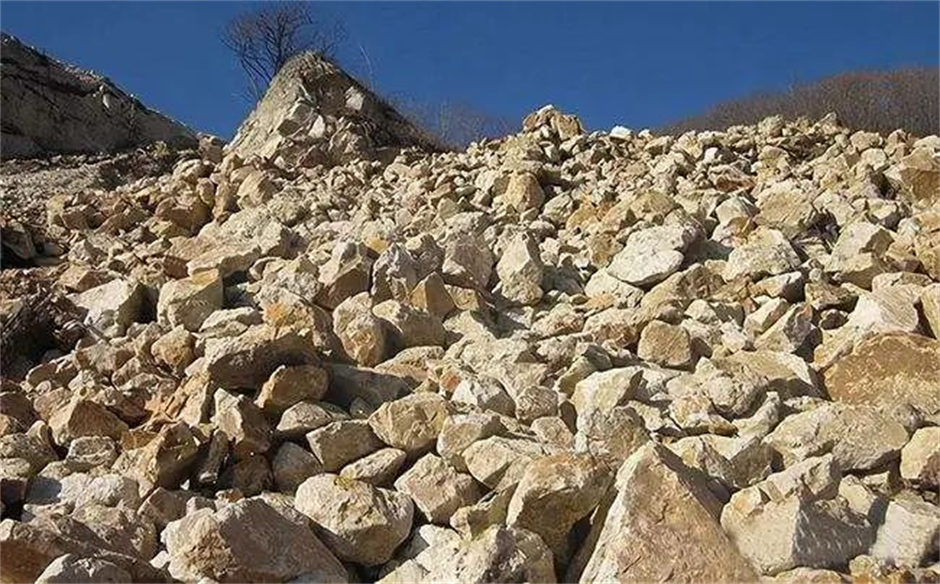

01 Picking (pointing) selection

On the mining face or the ore pile at the pit, the mica that has been separated from the monomer is selected, and it is generally suitable for large flake mica.

02 Friction beneficiation

According to the difference between the sliding friction coefficient of the flaky mica crystal and the rolling friction coefficient of the round gangue, the mica crystal and the gangue are separated. One of the equipment used is a slant plate sorter.

03 Shape beneficiation

According to the different shapes of mica crystals and gangue, the ability to pass through the sieve gap or sieve hole during sieving is different, so that mica and gangue are separated.

04 Wind selection

After the sand and gravel are crushed, the mica is basically in the form of flakes, while the gangue minerals are in the form of massive particles. After multi-level classification, special equipment is used for wind separation according to the difference in the suspension speed in the airflow.

05 Flotation

At present, there are two flotation processes: one is flotation of mica with amine collectors in an acidic medium; the other is flotation with anionic collectors in an alkaline medium, which needs to be de-slimed before selection, and needs to be selected many times.

06 Magnetic separation

Biotite and phlogopite have weak magnetic properties and can be selected by strong magnetic method; iron oxide and iron silicate impurities are often associated with muscovite, sericite and lepidolite, which can also be removed by strong magnetic separation. Magnetic separation equipment mainly includes dry and wet strong magnetic rollers, plate magnetic separators and vertical ring high gradient magnetic separators.

Peel off

Peeling raw mica into mica sheets of various specifications is called mica peeling. At present, there are three methods of peeling, which are manual, mechanical and physical and chemical, which are used for processing such as thick sheets, thin sheets, and tube mica.

Fine and ultra-fine grinding

There are two kinds of production of fine grinding and ultra-fine grinding of mica, dry method and wet method. In addition to crushing and grinding equipment, dry method also needs to be equipped with equipment such as screening and air classification. Wet production uses various wet grinding equipment, and wet grinding technology is the main development trend in the production of fine mica powder.

Surface modification

The surface modification of mica powder can be divided into two processes: organic surface modification and inorganic surface coating modification. The modified mica product can improve the mechanical strength of the material, reduce the molding shrinkage rate, good optical visual effect and improve the application value, etc.

Post time: Mar-07-2022