【Huate Mineral Processing Encyclopedia】Research and Application of Electromagnetic Elutriation Concentrator

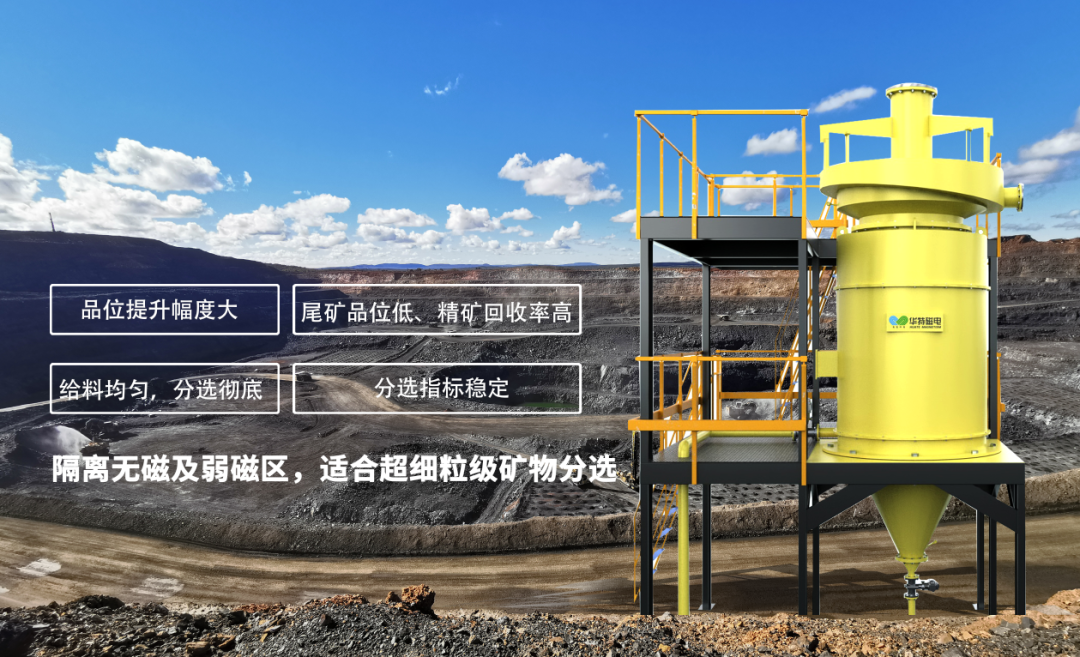

TCXJ series electromagnetic panning and concentrating machine is a new generation of electromagnetic concentrating equipment developed by Shandong Huate Company on the basis of domestic selected products. Comprehensive indicators such as recovery rate and water saving effect have been greatly improved.

Electromagnetic panning concentrator is mainly used for concentrating operation in magnetite concentrator. It comprehensively considers the comprehensive force field effect of magnetic force, gravity, centrifugal force and other forces, and can effectively reduce the content of impurities such as silicon, phosphorus and sulfur in magnetic ore.To obtain high-grade magnetite concentrates and intermediate products such as concentrates in the magnetic separation process, and obtain qualified final concentrates in advance.

1.Mineral taste greatly improved Low tailings grade and high concentrate recovery

2.Uniform feeding and thorough sorting The sorting index is stable

Isolate non-magnetic and weak magnetic areas,Suitable for ultra-fine-grained mineral sorting

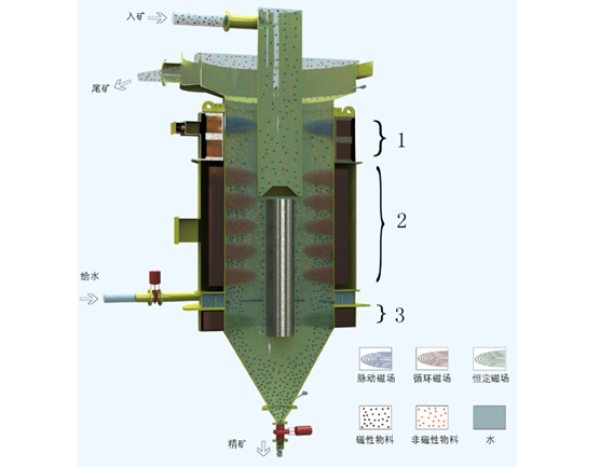

The electromagnetic panning and concentrating machine is mainly composed of feeder, overflow tank, excitation coil (tail control, circulation, compensation), sorting cylinder, outer cylinder, overflow adjustment, electric valve, electric hose valve, pressure transmitter , magnetic induction ring, mine distribution pipe, control system, etc.

The pulp is scattered into the separation drum in a “high pressure” state through the distribution pipe of the feeder, and the dissociated magnetite particles are repeatedly “washed” by the circulating magnetic field set in the beneficiation area in the middle of the separation drum. Complete separation of magnetic material and non-magnetic material is achieved, and the grade of concentrate is improved. After the magnetite that has not been selected in the selection area enters the tail control area, it will re-enter the selection area under the action of rising water flow, alternating magnetic field and magnetic induction ring for further selection to reduce the tailings grade. The concentrate enters the cone at the bottom of the equipment under the action of the auxiliary magnetic field in the compensation area at the lower part of the sorting drum, and is discharged from the lower concentrate pipe.

Application case of electromagnetic panning selection machine

Post time: Feb-24-2022