Steel slag, as the final waste slag produced by steel smelting, contains high iron elements. Due to its high density and high bulk density, it cannot be popularized and utilized in the construction industry. The precious iron resources have not been recovered well, resulting in a certain amount of waste. The steel slag should be recycled and reused through a certain magnetic separation process, and meet the requirements of the powder iron grade required by the iron-containing material for blast furnace smelting, so that the steel slag can be recycled. Can be better used in construction.

At present, a certain magnetic separation process is a more feasible method, and it is imperative to select suitable equipment to achieve iron separation and efficient recovery. The steel slag is ground to realize its dissociation, and then through the air dry magnetic separation of the powder ore, the feed ore, concentrate and tailings are respectively received, and the total iron grade is analyzed and analyzed to obtain the best process and equipment parameters. Provide appropriate technical support for actual production.

Steel slag properties

Steel slag is the waste slag produced by the use of high-magnesium lime, active lime and other auxiliary materials for decontamination and oxygen blowing in the steelmaking process, so it contains relatively high iron oxide, generally 20%-40%, and FeO content is more than Fe2O3 , the former is generally 15%-25%, while the latter is 5%-15%, both of which show weak magnetism.

Test equipment

The test equipment adopts the FX0665 powder ore air dry magnetic separator of Huate Company, which is mainly used for the pre-selection of magnetite before grinding or the production of qualified concentrate from powdered magnetite.

Powder Ore Air Dry Magnetic Separator

Working principle

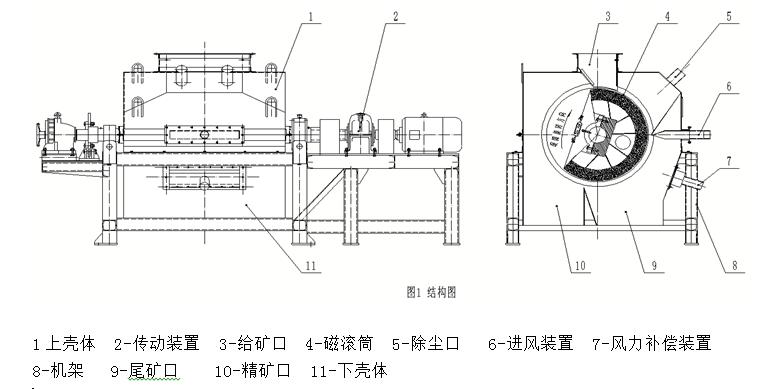

upper shell 2.transmission 3.Feed Hole 4.Magnetic roller 5.dust outlet 6.Air intake device 7.wind compensation device 8.frame 9.Tailings opening 10.Concentrate opening

lower shell

The working principle of the powder ore air dry magnetic separator is shown in the figure. The minerals are fed to the surface of the magnetic drum through the ore feeding port 3, and the magnetic minerals are adsorbed on the surface of the magnetic drum 4 under the action of the magnetic force, and rotate with the magnetic drum 4. During this process, the minerals on the surface of the magnetic drum 4 are subjected to the combined action of the magnetic pulsation of the large wrap-angle and multi-pole magnetic poles, the magnetic stirring device, the air inlet device 6 and the dust removal port 5, so that the impurities in the minerals and the poor conjoined organisms are effectively eliminated. Thereby, the grade of the concentrate is improved. After the selected minerals are rotated to the non-magnetic area with the magnetic drum 4, they are enriched into the concentrate port 9 under the action of gravity, centrifugal force and unloading device to become concentrate. The non-magnetic minerals or lean conjoined bodies are excluded from the tailings mouth 8 under the action of gravity and centrifugal force, and become tailings or medium ore.

Innovation and key technology of powder ore air dry magnetic separator

1.The vibrating feeder is used for feeding, and the parameters of the feeder can be adjusted to achieve uniform feeding;

2.The magnetic system adopts multi-pole, large wrap angle (up to 200-260 degrees), high field strength (3000-6000Gs) design, and the magnetic system structure can be changed according to the mineral properties to achieve reasonable beneficiation indicators;

3.The linear speed of the cylinder is adjusted within 1-20m/s, and the appropriate linear speed can be selected according to the nature of the ore; the cylinder is made of non-metallic material and is equipped with a magnetic stirring device to improve the concentrate grade;

4.It has a specific air knife structure, wind compensation device and dust removal device (appropriate parameters can be selected according to the nature and index requirements of the ore); the surface of the cylinder is provided with an unloading device, which can realize the clean discharge of the concentrate;

The FX powder ore air dry magnetic separator is mainly composed of a transmission device, a magnetic separation drum, a blower device, an induced draft dust removal device, a sedimentation collection device, etc. The magnetic field strength of the magnetic separation drum is 3500Gs. , magnetic force, rotating centrifugal force, etc., can achieve dry pre-selection of 0-5mm particle size magnetite or greatly improve the grade of fine powder magnetite. The main effects are as follows:

A.The selected grade of 0-5mm magnetite can be increased from about 10% to more than 40%. It can be used as pre-discarding before grinding, which can greatly improve the entering grade and improve the efficiency of the mill.

B.The selected grade of -74um and -45um fine-grained magnetite can be increased from about 10% to more than 60%, and the qualified concentrate can be directly obtained by dry selection.

Test method and analysis.

①Analysis of common elements and detection of metal materials.

②Preparation and purification of non-metallic minerals such as English, long stone, fluorite, fluorite, kaolinite, bauxite, leaf wax, baryrite, etc.

③The beneficiation of black metals such as iron, titanium, manganese, chromium and vanadium.

④ Mineral beneficiation of weak magnetic minerals such as black tungsten ore, tantalum niobium ore, pomegranate, electric gas, and black cloud.

⑤ Comprehensive utilization of secondary resources such as various tailings and smelting slag.

⑥ There are ore-magnetic, heavy and flotation combined beneficiation of ferrous metals.

⑦Intelligent sensing sorting of metallic and non-metallic minerals.

⑧ Semi-industrialized continuous selection test.

⑨ Ultrafine powder processing such as material crushing, ball milling and classification.

⑩ EPC turnkey projects such as crushing, pre-selection, grinding, magnetic (heavy, flotation) separation, dry raft, etc.

Post time: Mar-14-2022