【Huate Magnetoelectric Mineral Processing Experiment Center】provides you with complete solutions for mineral processing and sorting!

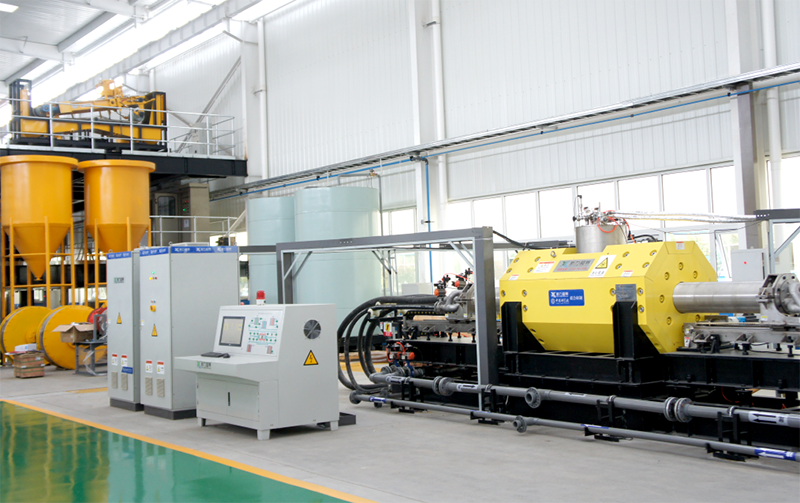

Huate Magnetoelectric Concentration Experimental Center belongs to “Shandong Provincial Key Laboratory of Magnetic Application Technology and Equipment”, “Sino-German Key Laboratory of Magnetoelectricity and Intelligent Mineral Concentration Technology Research and Development”, and is a “national-level magnetoelectric strategic alliance public service platform”. With a land area of 8,600 square meters, there are 120 full-time and part-time experimental researchers, including 36 with senior professional titles.It has areas such as crushing and grinding, material testing, superconducting magnetic separation, intelligent sensor separation, dry magnetic separation, wet magnetic separation, flotation and gravity separation, semi-industrial continuous separation, and powder complete processing test lines. There are more than 300 sets of mineral processing equipment and analysis and testing instruments. Equipped with advanced system facilities such as photovoltaic power generation, central air conditioning, water mist dust removal, and circulating water supply, it is one of the largest and most fully equipped professional laboratories for mineral processing and sorting in China.

The experimental center has a number of technological innovation achievements in mineral processing technology, technology, design and equipment, which are at the international leading level. , University of Science and Technology Beijing, North China University of Technology, Wuhan University of Technology, Shandong University of Science and Technology, Shandong University of Technology, Jiangxi University of Science and Technology, Suzhou Sinoma Nonmetallic Mining Industrial Design and Research Institute, Jinjian Engineering Design Co., Ltd., Yantai Gold Institute, Xingsheng Mining, etc. Colleges and universities jointly build laboratories and practice bases for production, education and research.Through the scientific research and experiments of intelligent sensor sorting, superconducting magnetic separation technology, permanent magnet and electromagnetic separation and recycling application technology, it provides scientific mineral processing technology, testing, design and other full-process technical services for the mining industry. It has carried out industrial promotion and application in several well-known mining groups at home and abroad, solved many key technical problems in the industry, and promoted the healthy development of green and smart mines.

The experimental center is oriented to the application technology of magnetic industry and military-civilian integration equipment, and provides mining enterprises and scientific research institutes with the separation and purification of various ferrous metals, non-ferrous metals, precious metals and non-metallic minerals; Mineral dressing tests such as combined beneficiation and semi-industrial continuous beneficiation; research on the comprehensive utilization of secondary resources such as various industrial tailings, tailings, metal waste, etc., to provide feasible technical guidance for the construction of the beneficiation plant.

1 Dry Magnetic Separation Equipment

Permanent magnet dry magnetic separator includes CTF powder ore dry separator, CXJ drum magnetic separator, CTDG bulk dry separator, FX air dry separator, CFLJ strong magnetic roller magnetic separator and other magnetic separation equipment. It ranges from 800Gs to 12000Gs. Mainly for magnetite, iron oxide ore, ilmenite, manganese ore and other ferrous metal minerals to pre-select tails under coarse-grained conditions, improve the grade of selected ore, and reduce production costs such as transportation, grinding, and beneficiation.

The powder ore air dry magnetic separator has the characteristics of multiple magnetic poles, large wrap angle, high field strength, magnetic stirring, wind device, frequency conversion speed regulation, etc. It is suitable for the separation and recovery of fine-grained magnetite and steel slag in arid and cold regions. .

2 Crushing and grinding equipment

Crushing equipment includes jaw crusher, roller crusher, hammer crusher, disc crusher, high pressure roller mill, etc. Grinding equipment includes steel ball mill, ceramic ball mill, rod mill, etc. The main purpose of crushing and grinding equipment is to crush and grind large pieces of ore to a qualified selected particle size.

High-pressure roller mills are divided into single-drive high-pressure roller mills and double-drive roller mills. They have the characteristics of constant pressure design, automatic deviation correction, edge material separation, alloy studs, strong wear resistance, high crushing rate, and large processing capacity. It is used for medium and fine grinding of ore and steel slag to reduce the grinding cost of subsequent ball mills. It can also be used in cement clinker, limestone, bauxite and other building materials industries.

3 Wet Magnetic Separation Equipment

Permanent magnet wet magnetic separation equipment mainly includes CTB drum magnetic separator, CTY pre-grinding pre-separator, SGT wet strong magnetic roller magnetic separator, SGB plate magnetic separator, JCTN refining and slag reduction magnetic separator, the magnetic field strength is from 600Gs ~11000Gs range. Mainly for magnetite, vanadium titanomagnetite, pyrrhotite, hematite, limonite, manganese, ilmenite, chromite, garnet, biotite, tantalum niobium, tourmaline, etc. Magnetic minerals are sorted.

The patented product JCTN refining and slag reduction magnetic separator adopts multi-pole, large wrapping angle, reverse rotation, double flushing and other devices, which is suitable for the selection, purification, desliming and concentration of fine-grained magnetite. At the same time, the loss of tailings magnetic iron can be reduced.

4 High gradient magnetic separation equipment

The patented product vertical ring high gradient magnetic separator has the characteristics of advanced oil-water composite cooling system, large magnetic field gradient, high magnetic permeability rod, adjustable pulsation, low magnetic heat decay, etc. Wet beneficiation of weak magnetic metal minerals such as iron oxide, manganese, chromite, ilmenite, wolframite, and rare earth. It can also be used for iron removal and purification of non-metallic minerals such as quartz, feldspar, kaolin, spodumene, fluorite, dolomite, bauxite, etc.

The electromagnetic slurry high gradient magnetic separator has the characteristics of unique electromagnetic coil design, oil-water composite cooling, high magnetic permeability medium, automatic program control, large magnetic field gradient, etc. It is suitable for the removal of non-metallic minerals or materials such as quartz, feldspar, and kaolin. Iron purification can also be used for wastewater treatment in steel plants and power plants.

5 Low temperature superconducting magnetic separation equipment

The CGC low-temperature superconducting magnetic separator developed in cooperation with the Chinese Academy of Sciences is the first at home and abroad, and the technical performance of the whole machine has reached the international leading level. , Short excitation time, low energy consumption, alternate sorting and other characteristics, can reach an ultra-high background magnetic field of 5.5 Tesla, which can effectively separate weakly magnetic minerals in fine-grained minerals. It is suitable for the separation and purification of rare, non-ferrous and non-metallic ores such as cobalt ore, rare earth, wolframite, chalcopyrite, pyrite, fluorite, kaolin, etc. It can also be used in the fields of sewage treatment and seawater purification.

6 Intelligent sensor sorting equipment

Jointly developed a world-class X-ray, near-infrared, photoelectric intelligent sensor sorting system with RWTH Aachen University in Germany to realize rapid identification, extraction and high-pressure air jet sorting of ore surface and internal features under ultra-high-speed conditions. Accurate, fast, large output, low energy consumption and other characteristics, solve the domestic blank ore dry pre-selection and discarding problems. Widely used in iron, manganese, chromium and other ferrous metal ores, gold, silver, platinum group and other precious metal ores, copper, lead, zinc, molybdenum, nickel, tungsten, rare earth and other non-ferrous metal ores, feldspar, quartz, fluorite, talc , dolomite, barite and other non-metallic minerals and dry pre-selection of coal.

The HTRX intelligent sorting machine is a multi-purpose intelligent sorting equipment independently developed by our company. It adopts the intelligent identification method to establish an analysis model suitable for different mineral characteristics, and analyzes the minerals and gangue through big data analysis. Digital identification, and finally the gangue is discharged through the intelligent injection system. HTRX intelligent sorting machine can be widely used in the beneficiation of weak magnetic ores such as gold, rare earth and tungsten ore.

7 Gravity and flotation equipment

Gravity separation equipment includes shaking table, centrifuge, cyclone, spiral chute, spiral concentrator, etc. It is suitable for the separation of metal minerals with large proportions such as iron ore, manganese ore, ilmenite, rutile, chromite, wolframite, etc. And the purification of non-metallic minerals such as quartz and feldspar. The combination of magnetic separation and gravity separation process can effectively improve the separation effect of products.

Flotation equipment includes XFD hanging flotation cell and 24L continuous flotation machine, which is suitable for gold, silver, copper, lead, zinc, tungsten, cobalt, molybdenum, rare earth and other non-ferrous metal ore beneficiation and quartz, iron ore and other minerals. Flotation to remove impurities.

8 Semi-industrialized continuous selection test production line

The semi-industrialized continuous selection platform includes continuous selection of non-metallic ores, ferrous metal ores and non-ferrous metal ores. The main equipment are ball mill, rod mill, tower mill, cyclone, three-dimensional vibrating screen, desliming bucket, drum magnetic separator, refining and slag reduction magnetic separator, plate magnetic separator, vertical ring and electromagnetic pulp Material high gradient magnetic separator, flotation machine, spiral chute, vibrating dewatering screen, deep cone thickener, disc filter and other grinding, grading, desliming, weak magnetic, strong magnetic, flotation, gravity separation, dehydration, Systematic facilities such as concentration and pressure filtration, and complete semi-industrial beneficiation test data can provide scientific and reasonable technical basis for the beneficiation plant.

9 Other mineral processing equipment

Other mineral processing equipment also includes powder processing, electromagnetic dry powder magnetic separator, electromagnetic panning machine, eddy current separator, etc. It is mainly used for ultra-fine grinding and classification of non-metallic minerals, iron removal from fine powder materials, purification of fine-grained iron ore concentrates, and separation of copper, aluminum, and iron from industrial metal waste.

Powder ultra-fine grinding and classification equipment has the characteristics of ultra-pure wear protection, scientific dust removal design, optimized configuration to reduce consumption, automatic control, ultra-fine grinding particle size, and high airflow classification efficiency. It is suitable for ultra-fine grinding and classification of non-metallic minerals such as calcite, limestone, barite, gypsum, quartz, feldspar, mullite, illite, pyrophyllite, etc. It can also be used in the field of ultra-fine powder processing such as cement and medicinal materials.

Shandong Hengbiao Inspection and Testing Co., Ltd. has a total area of more than 1,800 square meters, more than 6 million yuan in fixed assets, and 25 professional inspection and testing personnel, including 10 senior engineers and laboratory technicians. Through the review, the CMA inspection and testing qualification certificate has been obtained. It is a public service platform with national recognition and independent legal responsibility that provides professional inspection and testing, information technology consulting, education and training services for mining and metal materials related industry chain industries. Operates and services in accordance with CNAS-CL01:2018 (Criteria for Accreditation of Testing and Calibration Laboratories). It consists of chemical analysis room, instrument analysis room, material testing room, physical property testing room, etc. It has more than 70 major instruments and equipment such as Thermo Fisher X-ray fluorescence spectrometer and atomic absorption spectrometer, plasma emission spectrometer, carbon and sulfur analyzer, direct reading spectrometer, impact testing machine, and universal testing machine.

Post time: Apr-19-2022