HRS-ray transmission intelligent separator is a new intelligent separation system developed and manufactured by the company and Aachen University in Germany. It is suitable for the preconcentration and waste discharge of most nonferrous metals, ferrous metals and non-metallic ores. It can effectively increase the content of target minerals before grinding, greatly reduce the costs of grinding, reagents and manual production, and increase the production processing capacity and economic benefits.

1. Composition of separator

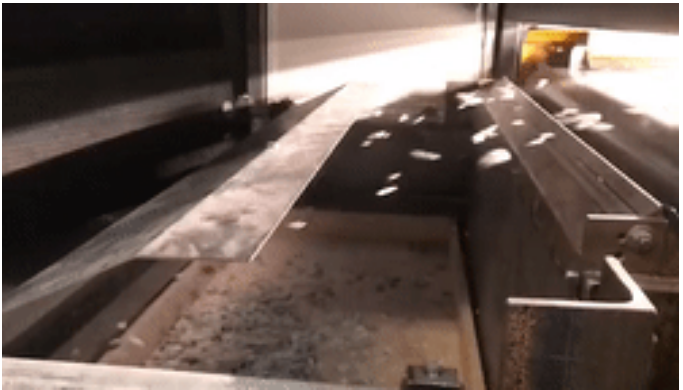

The intelligent separator is composed of feeding system, control and display system and separation system. The feeding system is the ore with qualified particle size and enters the feeder and conveyor belt from the feeding hopper; the control and display system is the core component of the forerunner in detecting the material transmission speed, the element content of the ore and issuing instructions; the separation system adopts mature jet separation, mainly by gas supply The system consists of a high-speed solenoid valve and a high-pressure nozzle. The high-pressure air is ejected through the high-pressure nozzle, and the ore is ejected away from the original trajectory to complete the separation of minerals.

2. Working principle of separator

The crushed ore is evenly scattered on the belt conveyor through the vibrating distributor. Under the high-speed operation of the belt, the ore is arranged on the surface of the belt in a single layer. The X-ray source imaging analysis system is set in the middle of the belt. When the ore passes by, the content of the target mineral elements is detected and analyzed one by one. After the signal is transmitted to the computer, the disqualification that needs to be discarded is calculated at high speed Check the ore, and send instructions to the mechanical separation system installed at the tail of the belt conveyor. The unqualified ore is thrown into the waste collection box under the action of external force, and the qualified ore will naturally fall into the concentrate product collection box.

Technical features

- Core components imported from Germany, mature and advanced.

- Through X-ray transmission, the elements and content of each ore are analyzed accurately by computer.

- According to the demand of sorting index, the separation parameters can be adjusted flexibly with high sensitivity.

- Equipment centralized control, high degree of automation operation.

- The conveying speed of material can reach 3.5m/s, which is adjustable and has large processing capacity.

- With uniform distribution device.

- Low energy consumption, less floor space and convenient installation

Application

The intelligent separator can be installed after coarse crushing or intermediate crushing and before the grinding machine to improve the grinding grade, increase the production capacity and economic benefits. It is suitable for the pre separation and discarding waste of ores in the size range of 15-30mm. It can be widely used in gold, silver, platinum, palladium and other precious metal ores, copper, lead, zinc, nickel, tungsten, tin, antimony, mercury, molybdenum, tantalum, niobium, rare earth and other non-ferrous metal ores; iron, silver, platinum, palladium, etc Black metal minerals, such as chromium and manganese; feldspar, quartz, calcite, talc, magnesite, fluorite, barite, dolomite and other non-metallic minerals.

In a word, most of the nonferrous, black and non-metallic minerals can be pre processed and discarded by intelligent separator after coarse crushing to qualified particle size, which can effectively improve the ore grade of grinding and dressing. It has a wide range of application and popularization value, and fills the blank in the field of non-ferrous metal mineral pre separation.

Post time: Nov-16-2020