Magnetic Separator Pipeline - Manufacturers, Factory, Suppliers from China

To fulfill the customers' over-expected satisfaction , we have now our strong crew to provide our greatest general assistance which incorporates promoting, gross sales, planning, creation, top quality controlling, packing, warehousing and logistics for Magnetic Separator Pipeline, Metal Detector , Ore Beneficiation , Classifier Mineral Dressing Machine ,Suspended Permanent Magnet Separator . Living by good quality, enhancement by credit history is our eternal pursuit, We firmly feel that soon after your visit we will become long-term associates. The product will supply to all over the world, such as Europe, America, Australia,Egypt, Hungary,Bangkok, French.We integrate design, manufacture and export together with more than 100 skillful workers, strict quality controlling system and experienced technology.We keep long term business relationships with wholesaler and distributors form more than 50 countries, such as USA, UK, Canada, Europe and Africa etc.

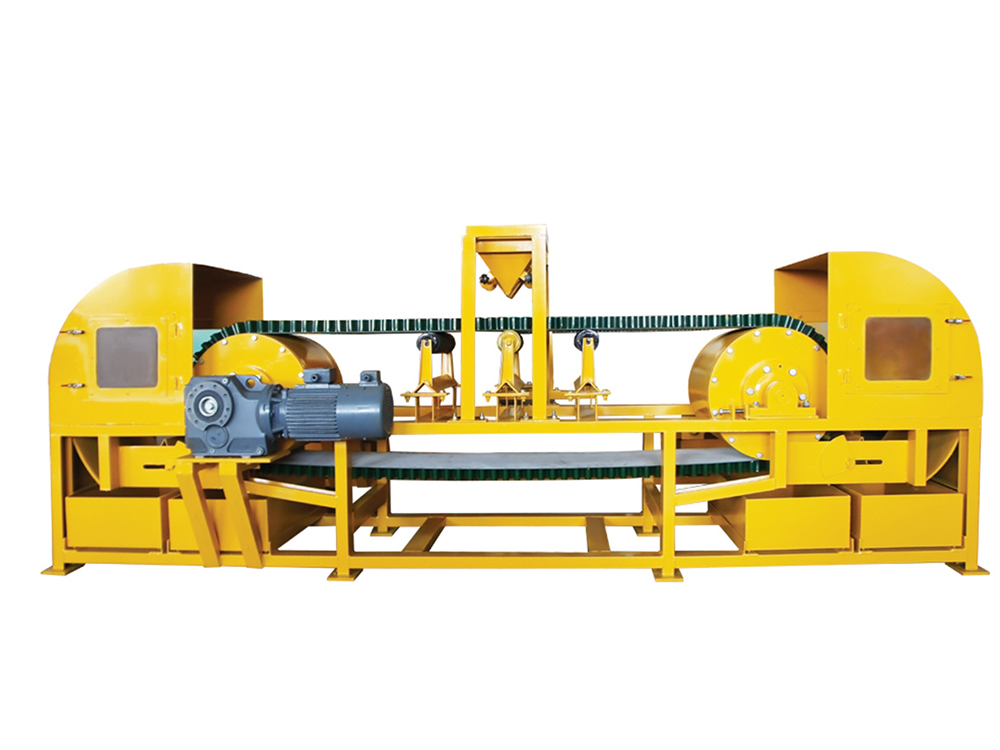

Related Products