On August 9th, Huate Magnet Group achieved a historic breakthrough at its headquarters, where four cutting-edge magnetic separation systems, including the world’s first and largest 7-meter intelligent WHIMS, were officially rolled off the production line and delivered. This milestone event has established the company’s global leadership in the field of ultra-large magnetic separation technology.

Global Industry Leaders Gather Together

Over 400 industry experts and corporate executives from the global mining and manufacturing sectors attended the event, including international academicians, heads of top industry associations, experts from renowned research institutions, as well as representatives from major global mining enterprises such as Baowu Steel, Angang Group, and Zijin Mining. Local government officials also attended to witness the occasion and acknowledged Huate Magnet’s contributions to advancing the development of high-end equipment manufacturing.

Innovation is at the Core of Huate’s Vision

Mr.Wang Zhaolian, Chairman of Huate Magnet Group, emphasized the company’s customer-centric development philosophy: “We have built a system integrating ultra-large equipment, customized processes, and full-lifecycle services, driven by real industry needs. Every piece of equipment is designed to create value for customers’ production and operations and enhance global mining efficiency.”

Industry experts praised this breakthrough as transformative. Internationally renowned academician Xu Zhenghe stated: “These pioneering products demonstrate Huate’s end-to-end innovation capability from basic research to commercialization, providing crucial support for the construction of green and low-carbon mines.” A responsible person from the China Heavy Machinery Industry Association added that this technology fills global industry gaps and drives the industry towards a “greener, smarter, and higher-performance” direction.

Focus: Highlights of Transformative Technologies

1. 7-Meter WHIMS(LHGC-7000)

As the largest machine of its kind in the world, this 12.8-meter-tall and 860-ton system with a magnetic field strength of 1.8T has set new industry benchmarks: it can process over 1,600 tons of low-grade hematite and 900 tons of quartz sand per hour, with a processing capacity 10 times that of traditional 3-meter models; the energy consumption per ton of ore is only 0.1-0.2 kWh, reducing project investment by more than 40%; it has a wide range of applications, including wet separation of weakly magnetic ores (hematite, limonite), tailings recycling, and iron removal and purification of non-metallic minerals such as quartz.

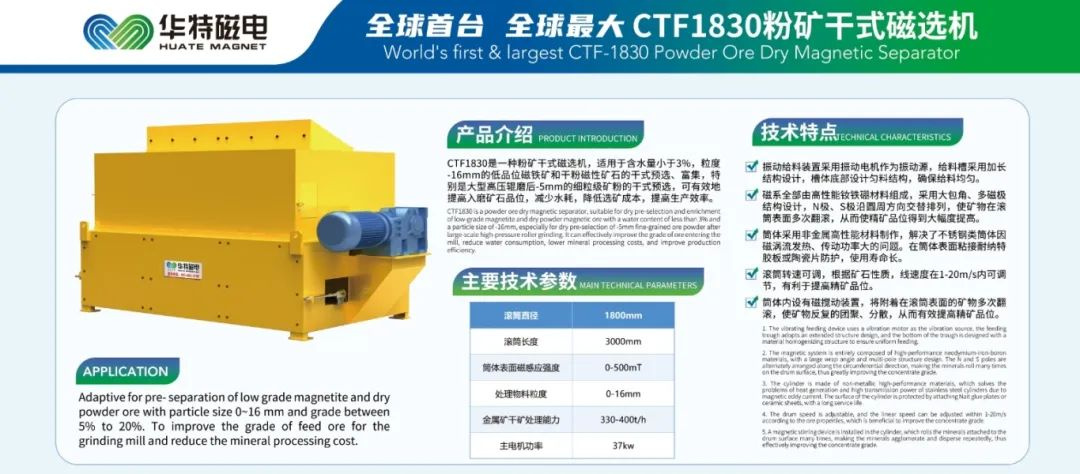

2. CTF-1830 Dry Powder Ore Magnetic Separator

Designed specifically for dry preconcentration of low-grade magnetite (with moisture content < 3% and particle size ≤ 16mm), it is equipped with a high-performance NdFeB magnetic system and an adjustable drum speed (1-20 m/s) to improve concentrate grade; it processes 330-400 tons of dry ore per hour, reducing water usage and operational costs, making it an ideal choice for water-scarce mining areas.

3. TCY-1530 High-Intensity Magnetic Titanium Preconcentrator

Focusing on dry separation of low-grade ores (with particle size ≤ 3mm), its 1000mT magnetic field strength enables precise separation of magnetically differentiated minerals such as ilmenite and chromite; the non-metallic drum design reduces energy loss, and the ceramic surface protection extends equipment life; it processes 120-150 tons per hour, enhancing the efficiency of mineral concentration.

Building a Global Cooperation Network

During the event, Huate Magnet signed strategic cooperation agreements with leading domestic mining groups and international clients, aiming to deepen cooperation in the field of mineral processing technology. Guests visited Huate’s intelligent production base, including the intelligent WHIMS future factory and R&D laboratories, to gain an in-depth understanding of its superconducting magnetic separation technology and digital control systems.

“This launch is not only a milestone for Huate but also a major step forward for global mining sustainability,” said Mr. Wang Qian, CEO of Huate Magnet Group will focus on global carbon emission reduction goals, making “Huate Intelligent Manufacturing” a core supporting force for efficient and environmentally friendly mineral resource development.

Post time: Aug-15-2025