Efficient Sharpener! Huate high frequency pulsating powder ore wind magnetic separator in ilmenite ore sorting application

Ilmenite is an oxide mineral of iron and titanium, also known as titanomagnetite, which is the main ore for refining titanium. Ilmenite is heavy, grey to black with a slight metallic luster. The crystals are generally plate-like, with crystals grouped together in massive or granular form. The composition is FeTiO3 with TiO252.66%, which is the main mineral for extracting titanium and titanium dioxide. The FCX high frequency pulsating pulverised wind magnetic separator developed by Huatech Magneto is suitable for the selection and purification of fine-grained dry ilmenite and magnetite after high-pressure roller mill, and also has a good sorting effect for the recovery of fine-grained steel slag magnetism.

Product technical characteristics

■ The vibrating feeding device adopts vibrating motor as the vibrating source, the feeding trough adopts lengthened structure design, and the bottom of trough body is designed with screed structure to ensure the uniform feeding.

■ The magnetic system adjusting device adopts the reducer structure adjusting method, which is convenient and easy to operate.

■ The magnetic system is made of high-performance NdFeB material, adopting the design of large wrapping angle and multi-pole structure, with the N pole and S pole arranged alternately along the circumference, so that the minerals are tumbled on the surface of the drum for many times, which improves the grade of concentrates greatly.

■ The connecting plate between the magnetic yoke and the main shaft is made of non-conducting stainless steel, which obviously reduces the magnetic leakage, prevents the bearings at both ends from being magnetised and improves the service life.

■ The cylinder is made of non-metallic high-performance materials, which solves the problem of stainless steel cylinder heating due to magnetic eddy current and high transmission power. The surface of the cylinder is protected by Nylon plate or ceramic sheet, which has a long service life.

■ The shaft end of the drum adopts the combined sealing structure of multi-groove labyrinth mechanical seal and rotating shaft lip seal, which effectively avoids debris from entering the bearing and causing bearing damage. Both ends of the drum are equipped with shaft sleeve structure to prevent damage to the main shaft after bearing damage.

■ The speed of the drum is adjustable, according to the nature of the ore, index requirements, the linear speed can be adjusted within 1-20m/s. The higher the speed, the higher the magnetic tumbling speed. The higher the rotational speed, the more magnetic flip, more conducive to improve the grade of concentrate.

■ There is a magnetic stirring device in the cylinder body, the minerals attached to the surface of the drum will be tumbled for many times, with a large wrap angle, narrow magnetic poles, multi-pole magnetic system, so that the minerals are repeatedly agglomerated and dispersed, thus effectively improving the grade of the concentrate.

Application Case

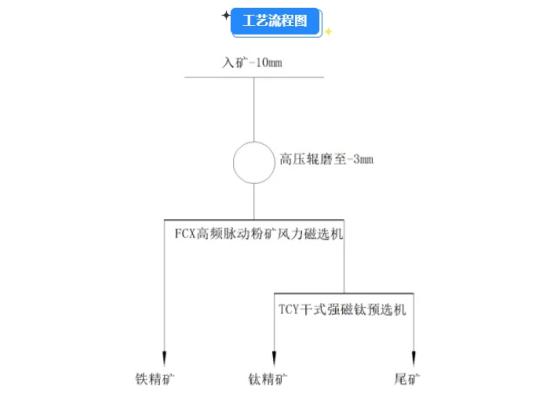

A ilmenite ore in Xinjiang, with a grain size of -10mm, rolled to -3mm by high pressure roller mill, passed through a section of FCX high frequency pulsating pulverised wind magnetic separator, and the tailings were then enriched with titanium by TCY dry strong magnetic titanium pre-selector.

Application Data

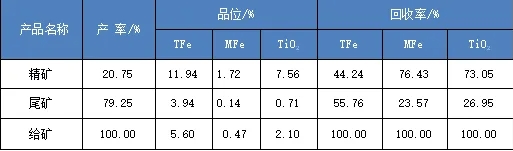

FCX high-frequency pulsating powder ore wind magnetic separator sorting data

-10mm ilmenite ore is ground to -3mm by high pressure roller milling, through FCX high frequency pulsating powder ore wind magnetic separator, drum line speed 3m/s, after a section of magnetic separation, the grade of raw ore MFe is increased from 4.23% to 21.96% of concentrate MFe, tailings MFe grade is 0.47%, and the recovery rate of concentrate MFe is 90.83%.

TCY dry strong magnetic titanium pre-separator sorting data

FCX high-frequency pulsating powder wind magnetic separator tailings through the TCY dry strong magnetic titanium pre-separator titanium enrichment, drum line speed 2.2m/s, raw ore TiO2 grade from 2.10% to concentrate 7.56%, tailings TiO2 grade 0.71%, concentrate TiO2 recovery rate of 73.05%.

Applications

Post time: May-16-2024