In recent years, mining companies have put forward higher and higher requirements for the automation control level of mineral processing equipment.With the development of 5G communication, cloud storage and big data technology, the application of the Internet of Things technology in mineral processing equipment has been promoted.In order to meet the needs of the market, we have proposed the framework of the Internet of Things + mineral processing equipment.

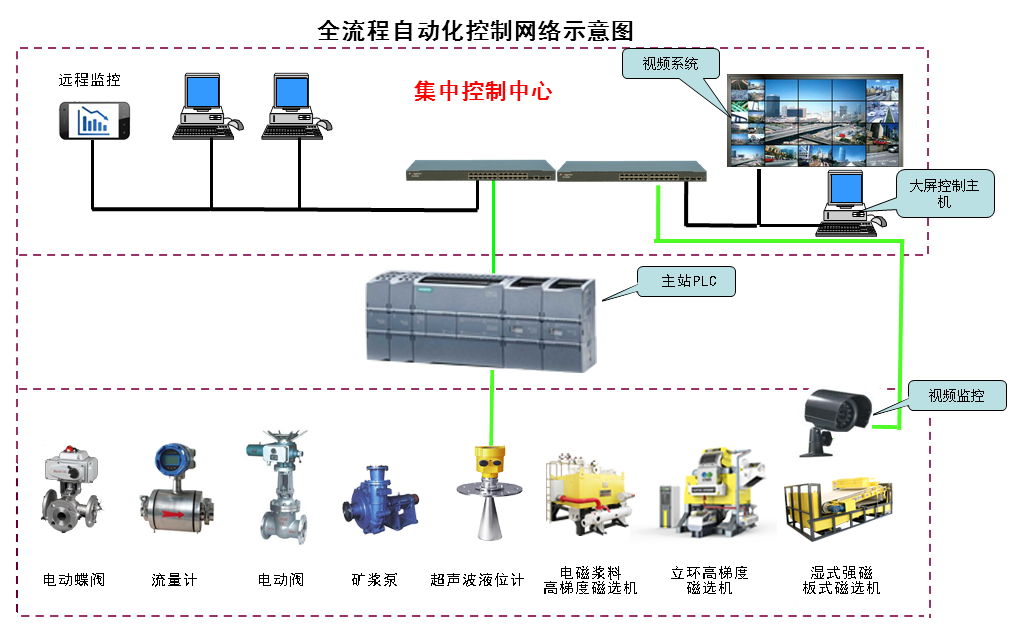

The Internet of Things + mineral processing equipment has a four-layer structure: equipment layer, network communication layer, cloud server layer and application layer.

Equipment layer: All kinds of sensors are used to collect real-time operating data of the equipment, and digitally process it through PLC to control the operation of the equipment.

Network communication layer: The on-site IoT communication module reads the data in the PLC, communicates with the cloud server through the wireless 4G/5G network, and transmits the data to the cloud server.

Cloud server layer: storage device operating data, configure and visualize important data, and use it at the application layer.

Application layer: The authorized network terminal can log in at any time to check the operating status of the device. The administrator can log in to modify the equipment program with the user’s authorization to meet user operation requirements.

The practical application of the Internet of Things + mineral processing equipment.

The wireless transmission is not restricted by space and region, and it can be used wherever there is a mobile phone signal.The beneficiation equipment with the function of the Internet of Things, through the Internet of Things module, collects data and transmits instructions nearby, and sends it to the cloud through the wireless network. The central control room reads the cloud equipment data and transmits instructions through the Internet, which is free from geographical restrictions. Save the signal cables and communication optical cables in the middle.

Authorized users can log in to the cloud platform to view device operating information anytime and anywhere. Device operating data is stored in the cloud server, and can view not only real-time data but also historical data.When equipment alarms and malfunctions occur, the system will promptly push the information to the maintenance contact, reducing the downtime caused by equipment maintenance.Professional engineers will also regularly check operating data, predict failures, and remind users to maintain in advance to avoid equipment failures.

Through the cloud service platform, the remote network terminal can upload, download and debug the software of the controller at the device layer, saving costs and debugging time;When equipment fails or needs to adjust process parameters, experts can use the on-site video and equipment data provided by the Internet of Things platform to help solve the problem quickly and effectively on site.

The universal application of the Internet of Things + mineral processing equipment in mineral processing enterprises will promote technological innovation in the mineral processing industry and promote the construction of digital, intelligent, informatized and automated enterprises.It not only promotes the deep integration of industrialization and informatization of mineral processing enterprises, but also improves the economic and social benefits of mineral processing enterprises.

Post time: Mar-09-2021